1. Introduction Capacity Management

The Capacity Management function on S/4 Hana is similiar like SAP ERP. Compared to SAP APO (ERP) or PP/SNP-DS (S/4) the functionality is Basic. An alternative could be the SAP Integrated Business Planning (IBP) with its different modules.

The following refers to a Standard S/4 Hana solution without PP/SNP-DS. In addition intercompany processes with non-SAP ERP being considered as well.

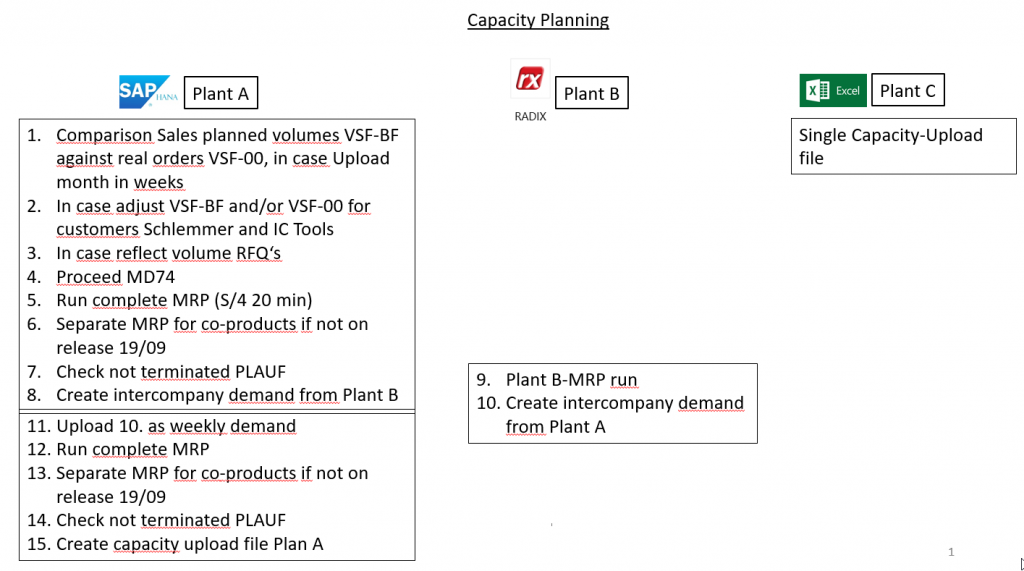

Following steps have been performed to achieve Capacity Constraint report:

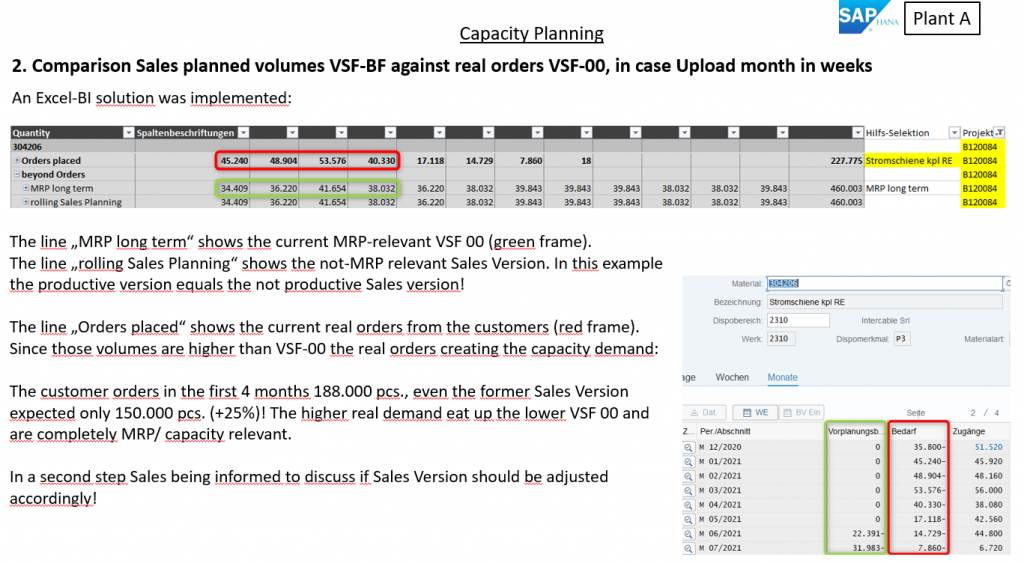

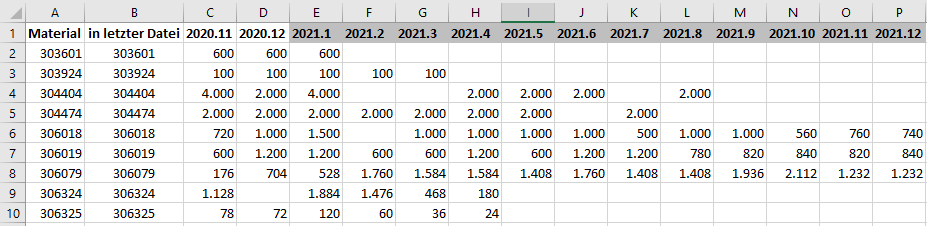

2. Comparison Sales planned volumes against real orders

One solution is following EXCEL-BI solution:

Another option can be following:

Call-Off AnalysisHere is an example where higher maintained MRP relevant VSF 00 volumes creates higher demand compared to real orders. Consequently more capacity is being blocked and pre-material being ordered:

3. Check not terminated PLAUF

It’s recommended to check for not terminated PLAUF since those will not create capacity on the workstations as well knock-down levels.

- Run Query „PLAUF“

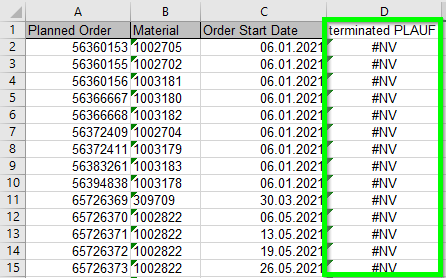

- The result is a list of terminated PLAUF:

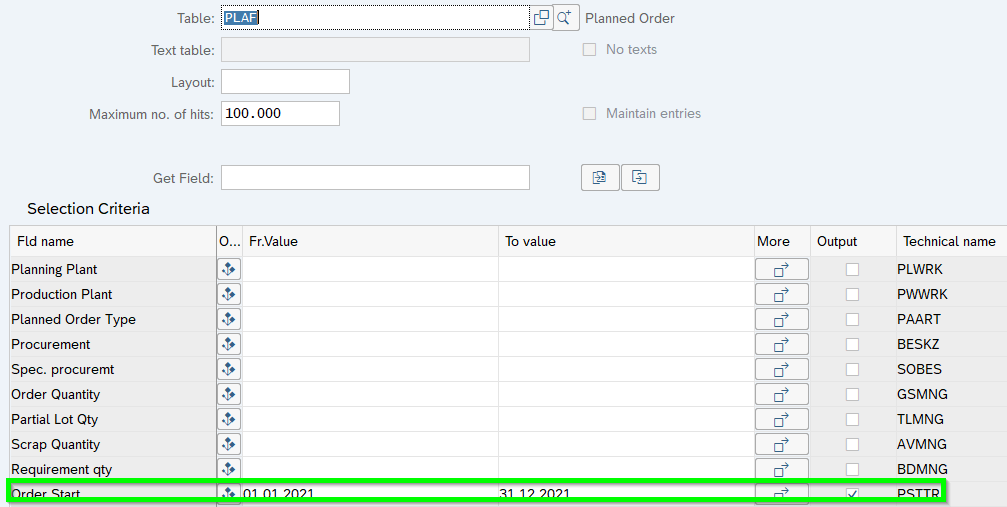

- Now you need to retrieve a list of all PLAUF via SE16N table PLAF:

- Then check both lists via VLOOK which PLAUF were not terminated and check the reason:

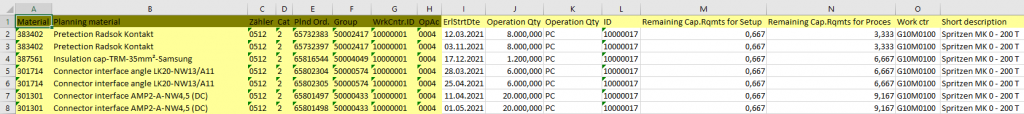

4. Create Capacity demand files via Query

As long as IBP S&OP solution was not in place a SAP-Excel solution is used. To run capacity planning the complicated part is the demand side and not the offer side. The capacity offer is normally not changing and simulation parameters like OEE, qty. of machines can be adjusted quickly for simulations.

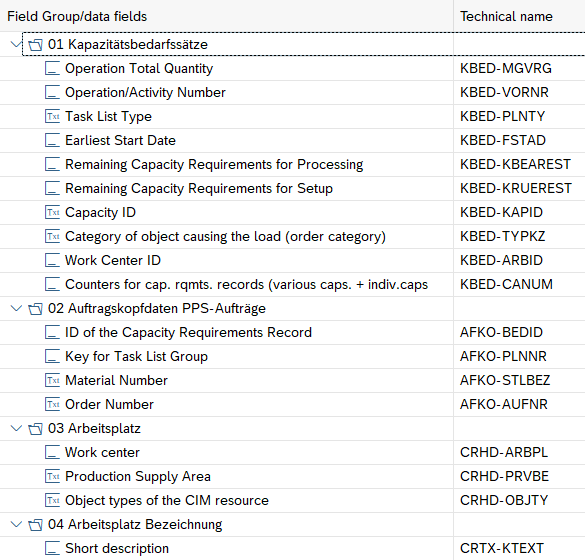

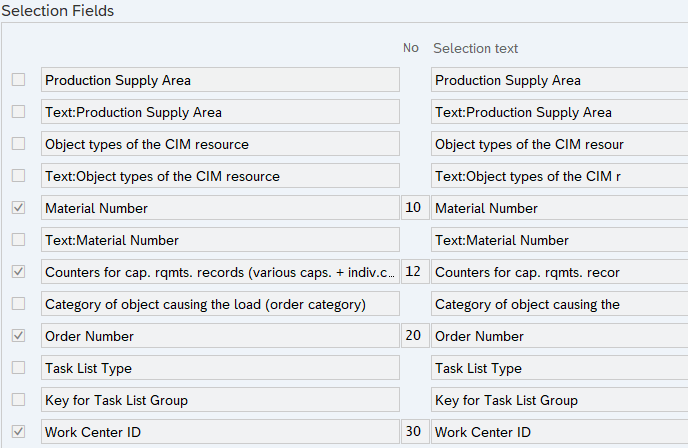

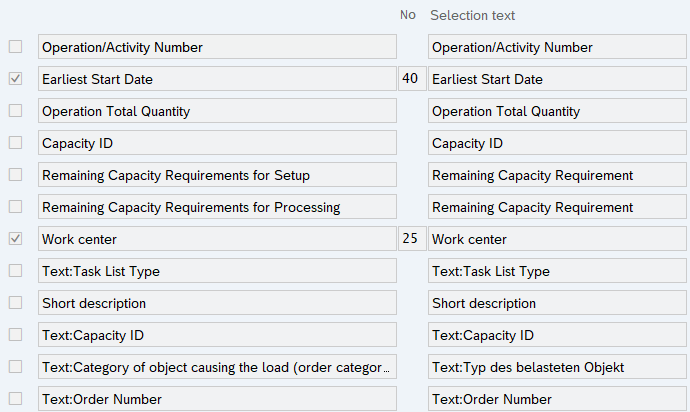

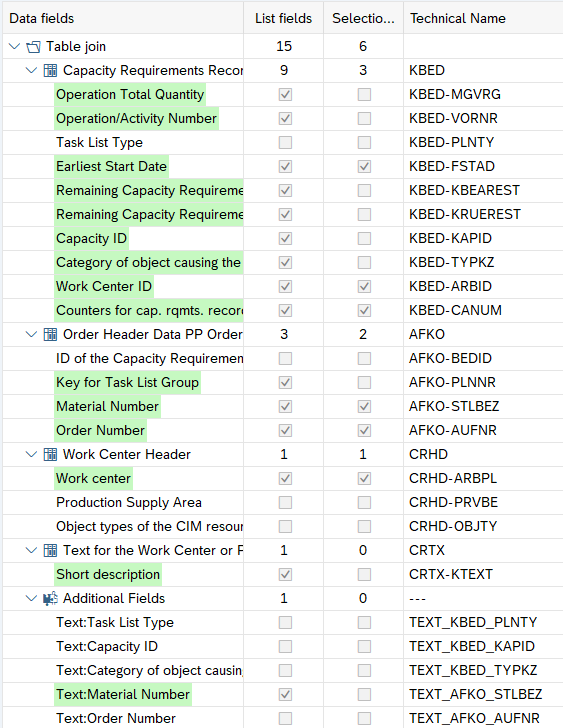

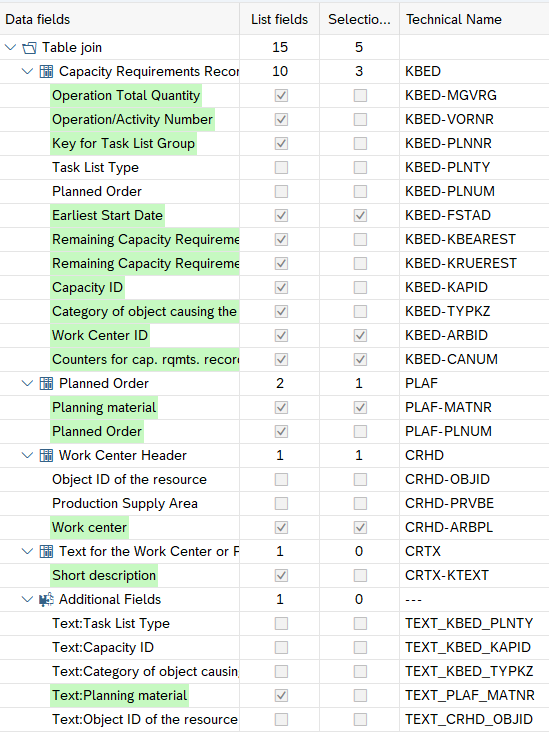

- SQ02-FAUF:

- SQ01-FAUF:

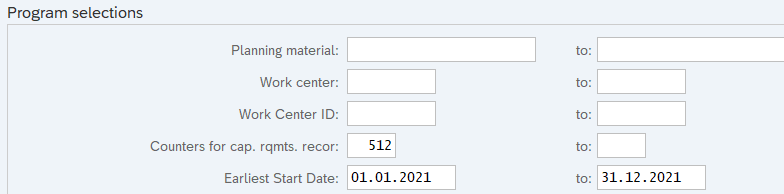

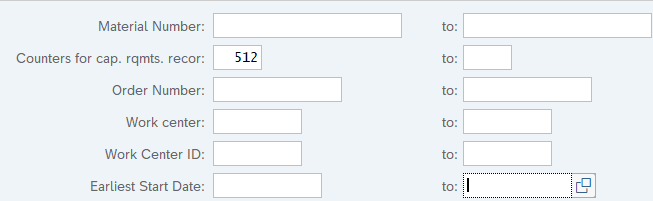

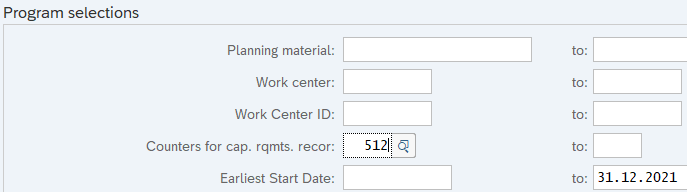

- SQ00-FAUF: Select counter 512 for machine or 1024 for workers

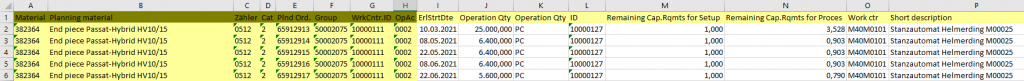

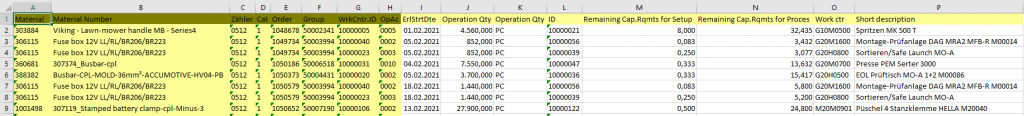

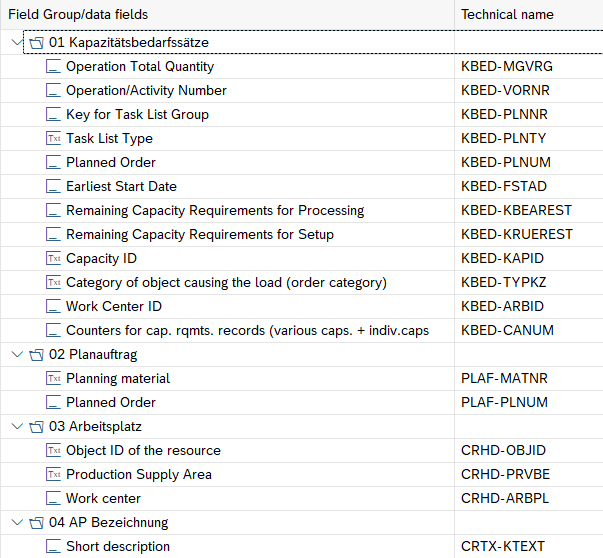

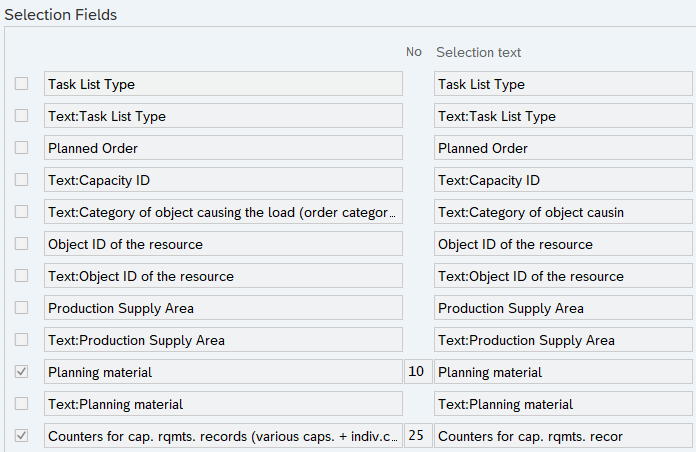

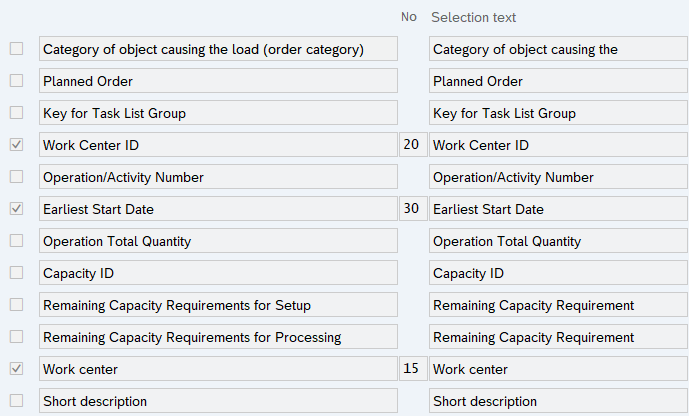

- SQ02-PLAUF: Column-wise some structure being created to add later FAUF and PLAUF list in one sheet:

- SQ01-PLAUF:

- SQ00-PLAUF: 512=Machine and 1024=workers

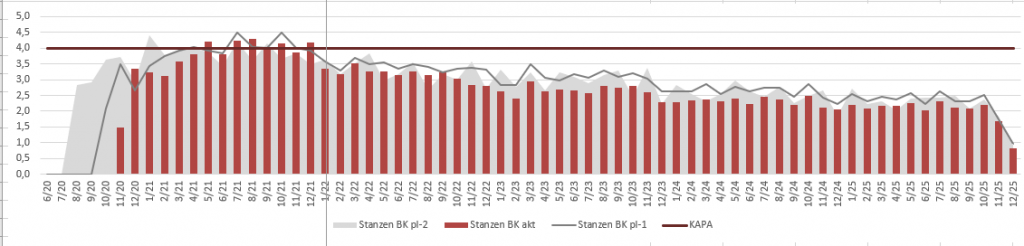

- Capacity Chart: Here is an example

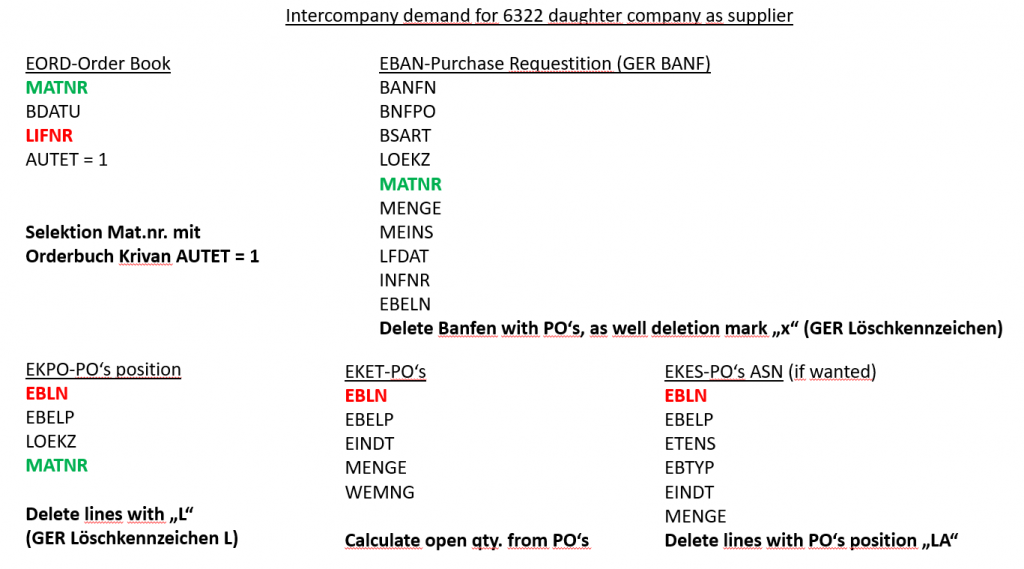

5. Intercompany Demand

In our current IT System set up the intercompany production sites do not yet have SAP system. Therefore the intercompany demands out of SAP system needed to be created.

As often a query being used. Here is the overview:

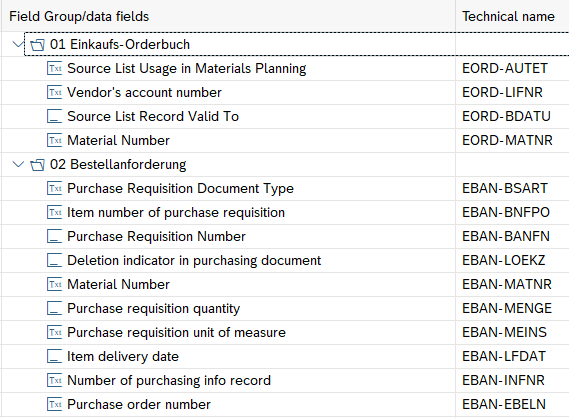

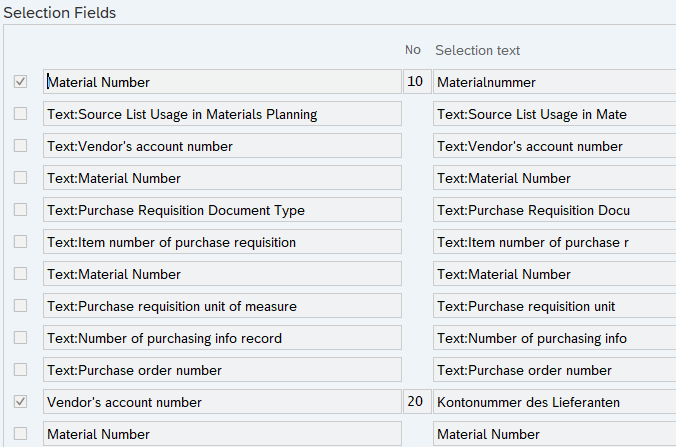

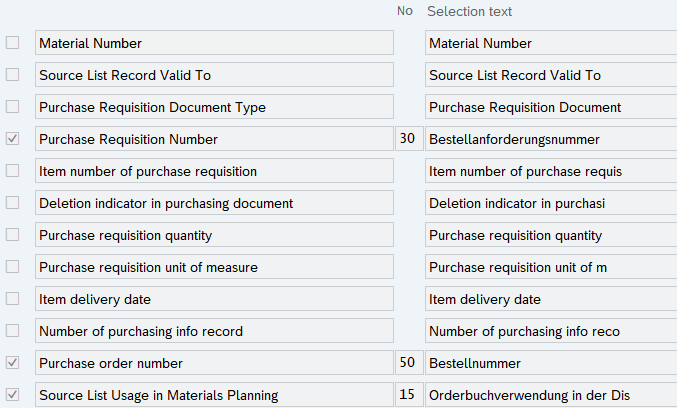

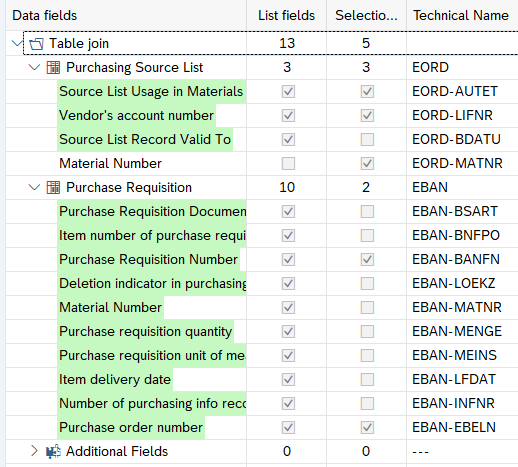

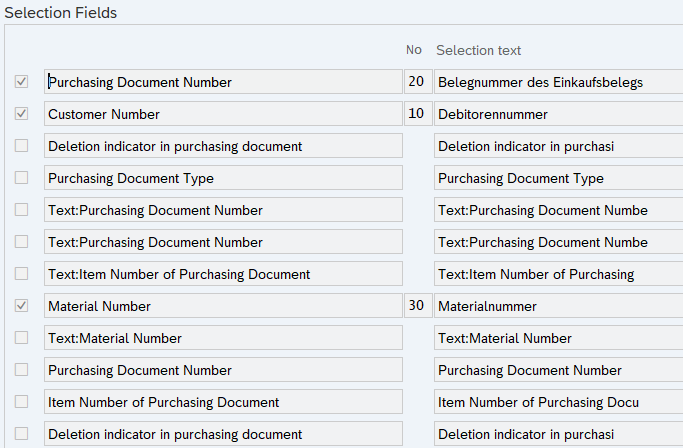

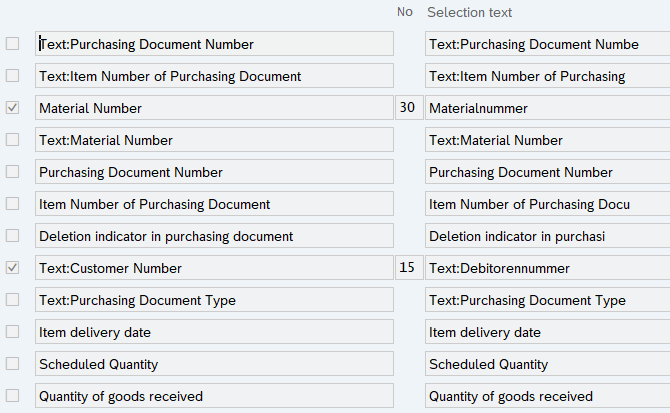

- SQ02-Purchase Requisition

- SQ01-Purchase Requisition

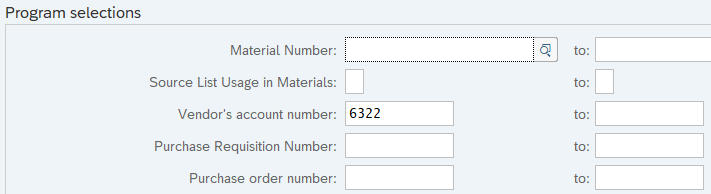

- SQ00-Purchase Requisition: Select Vendor/ intercompany e.g. 6322

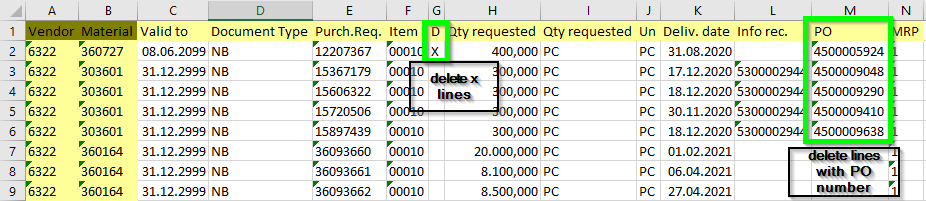

- Delete lines with „x“ (already deleted Purchase Requisition) as well lines which include PO number:

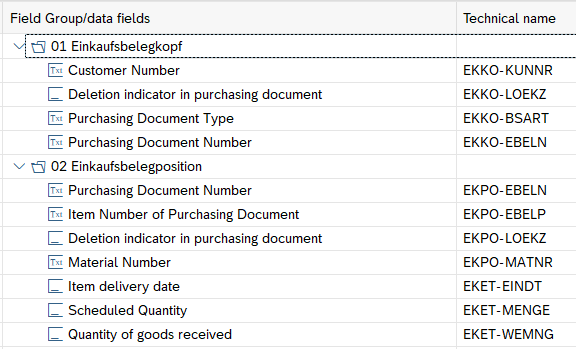

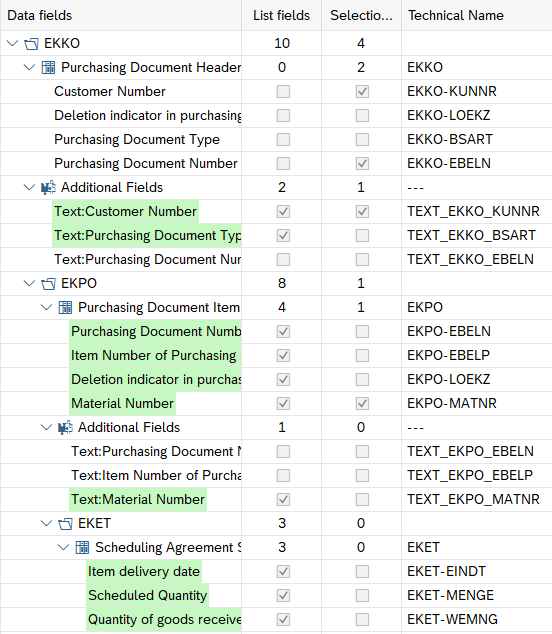

- SQ02-Purchase Orders

- SQ01-Purchase Orders

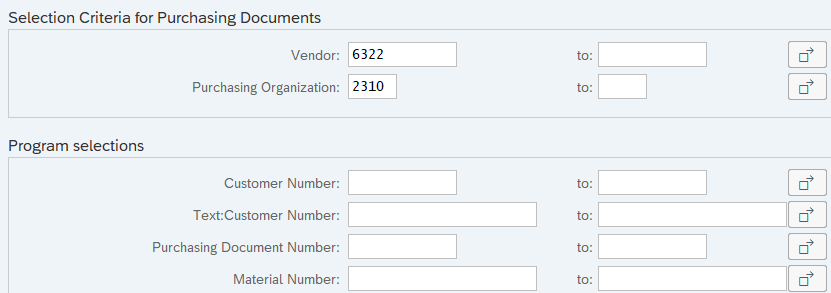

- SQ00-Purchase Orders: Vendor 622 intercompany production site

- Delete lines where column E shows „L“ for deleted PO’s. Also add additional column M to calculated open PO’s. Delete those lines which are zero or higher than zero. Make random check if the resulted PO’s are still open in MD04:

- Finally put open Purchase Requisition and open PO’s together:

6. Standard ERP Capacity Transaction

- Capacity Offer (GER Kapazitätsangebot): Maintain the offer within the work center under sheet Capacities

- Capacity Demand (GER Kapazitätsbedarf): Values in hrs. per capacity type (machine/ person) are being created by terminated PLAUF/ FAUF

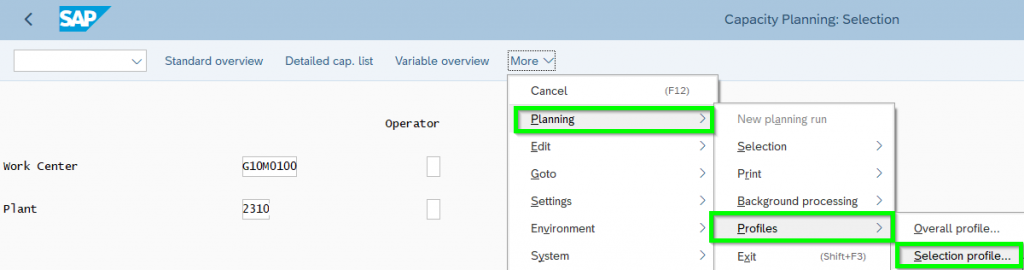

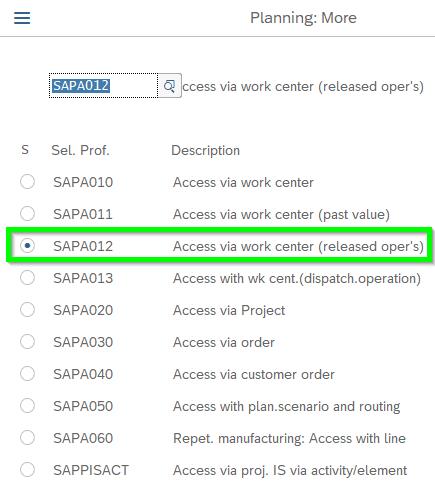

- Standard Overview (CM03/07): Before the list being created the relevant Selection profile needs to be seletected:

In this example only the released FAUF should be selected:

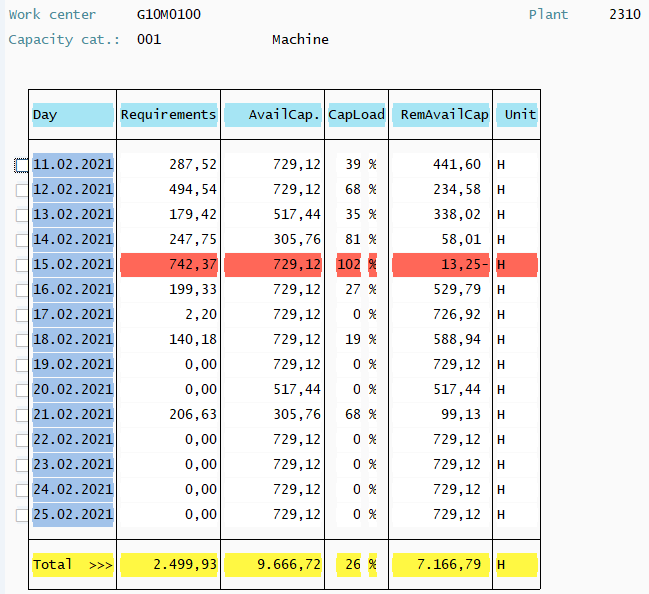

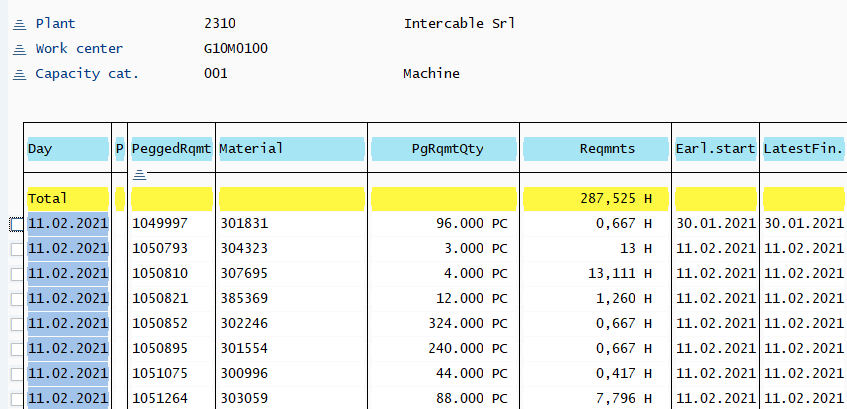

Next step you can see the details of a specific selected date. The calculation can be customized. In our example the whole capacity hrs. for 001 machine will be displayed on Scheduled End Date (GER Terminierter Ende Termin):

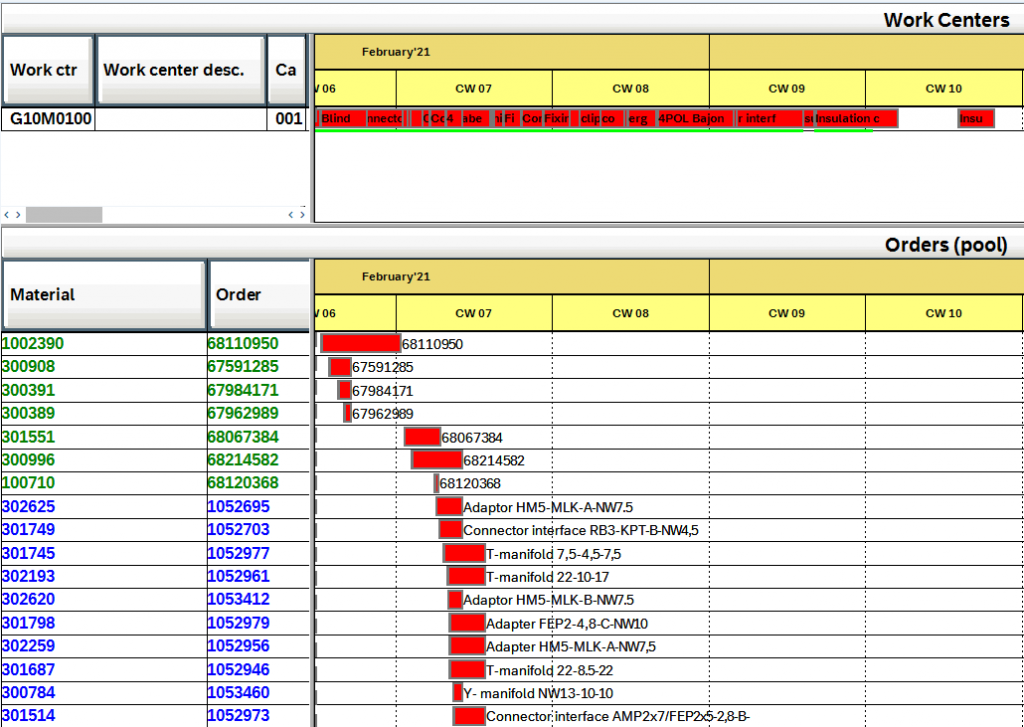

- Capacity Leveling / Planning Table (CM21): The normal ERP offers a Basic Planning Table. Advanced Production Planning needs external MES Systems (e.g. ProSes, Hydra or Cyberplan) or SAP PP/DS to make finite planning. Green = PLAUF and Blue = FAUF. TOP = Capacity Offer LOW = Capacity Demand