1. SAP Cycle

To understand SAP the SAP cycle with ist SAP Elements needs to be understood:

2. Scheduling (GER Terminierung)

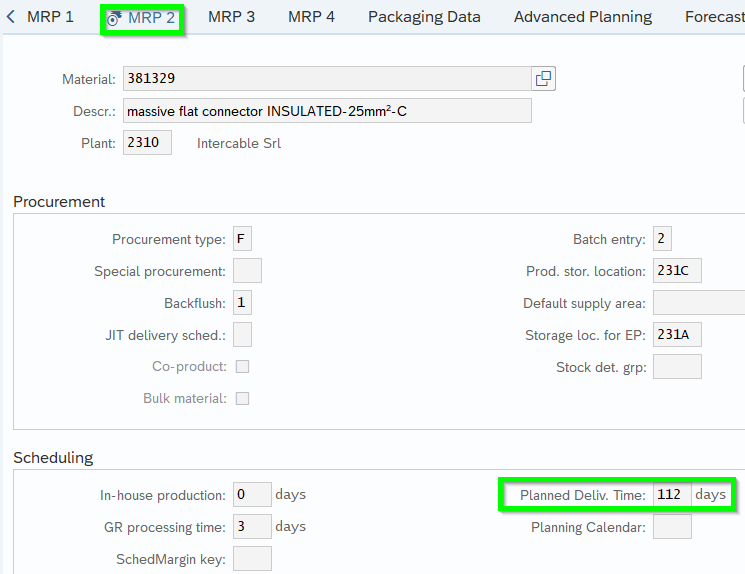

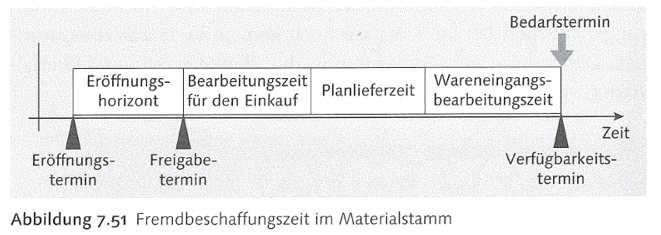

A. Procurement Type (GER Beschaffungsart) MRP2: determines if PLAUF or Purchase Requisition being created. Purchase Requisitions are not linked to supplier yet (only after switched to PO) Hence the Planned Delivery Time (GER Planlieferzeit) out of MRP2 is used:

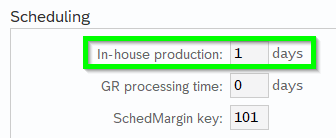

B. Basic Dates (GER Eckterminbestimmung für Planaufträge): The parameter „In-house production“ (GER Eigenfertigungszeit) from master data MRP2 being used:

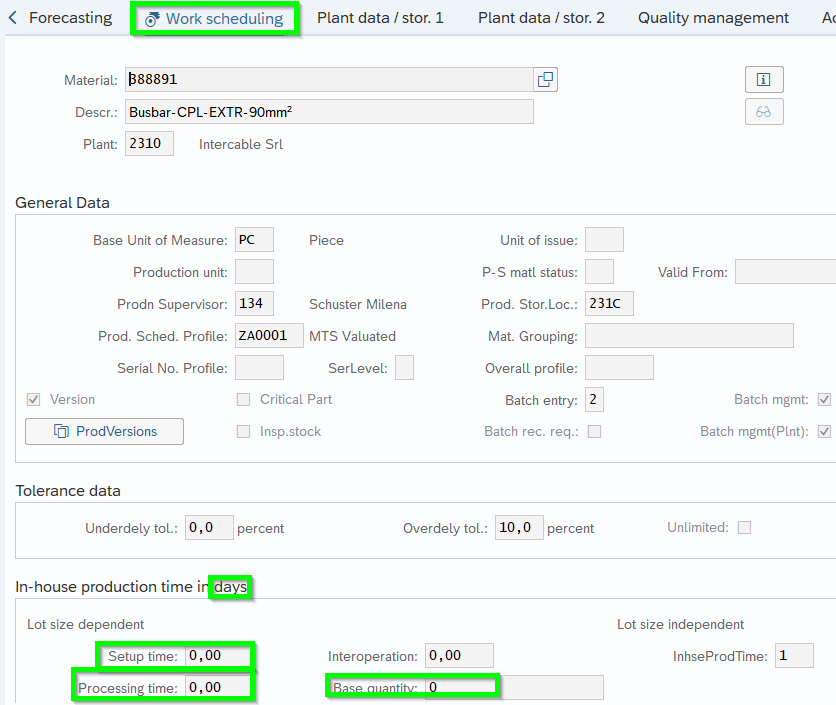

The parameter does not consider any qty. so in this example the time is 1 working day even you produce 1 or 1.000 pcs. If you like to consider qty. maintain following parameters:

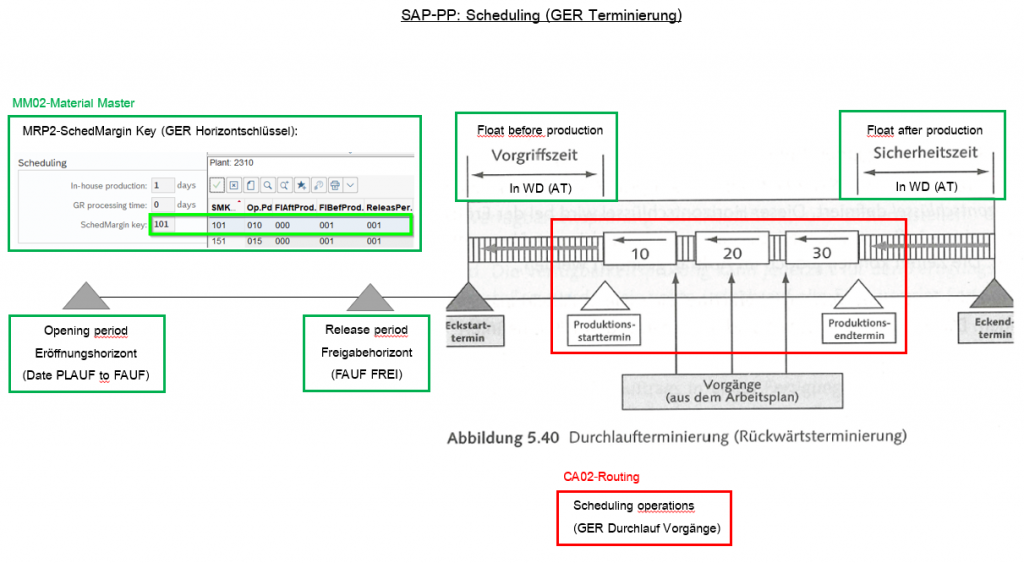

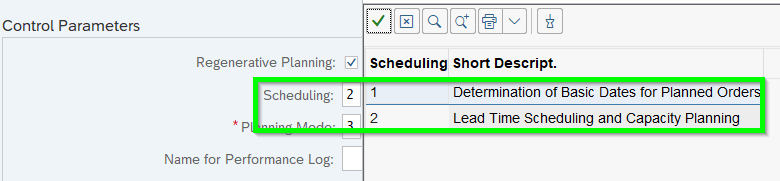

C. Lead Time Scheduling (GER Durchlaufterminierung): The cycle-time parameters from Routing will be used, so the result is more precise. Since the performance of the S/4 Hana has been increased from normal ERP this setting is the Standard and recommended.

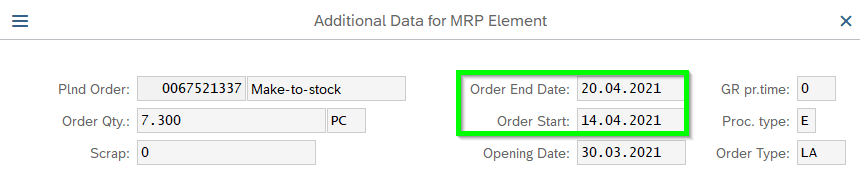

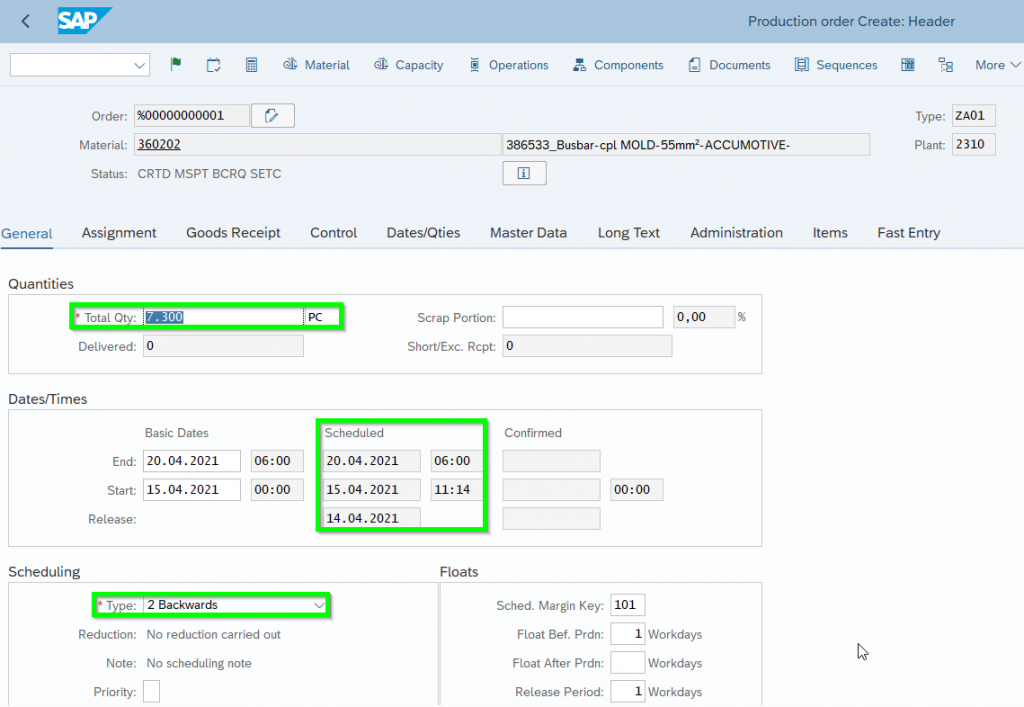

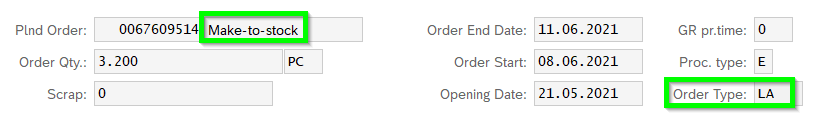

Example: PLAUF

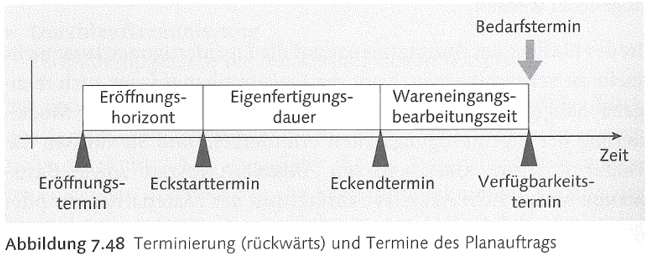

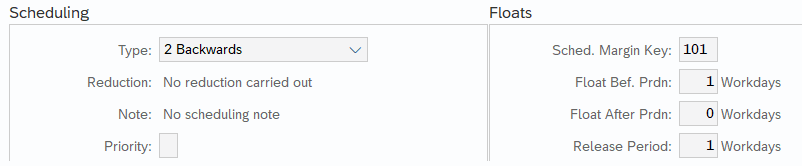

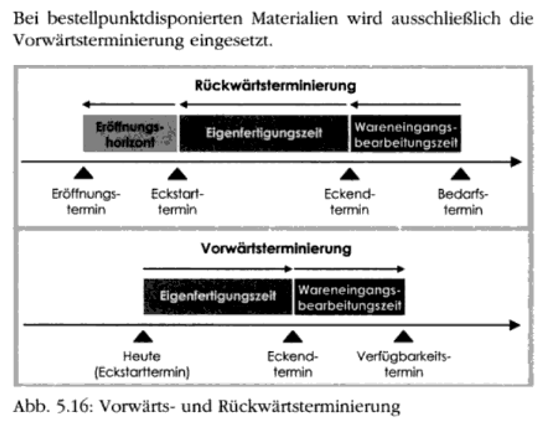

The type of scheduling can be set: 2 Backwards (GER Rückwärtsterminierung) / 1 Forward (GER Vorwärtsterminierung):

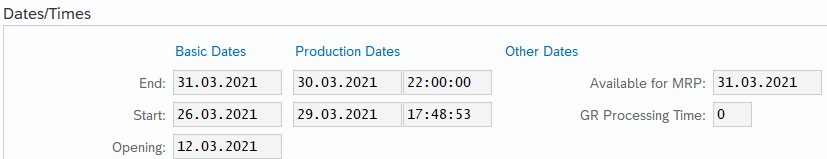

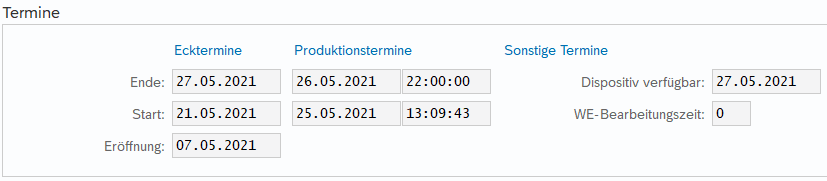

- Backward scheduling: From Order End Date (GER Eckendtermin) the other dates being terminated via backward calculation

- Forward scheduling: From Order Start Date (GER Eckstarttermin) the other Dates being terminated voa Forward calculation

- Order End Date (GER Eckendtermin) = Date on which the components need to be available

- Float after production (GER Sicherheitszeit) = Number of working days as a buffer between Production End Date (GER Produktionsendtermin) and Order End Date (GER Eckendtermin) (i.e. machine malfunction)

- Production End Date (GER Produktionsendtermin) = Date on which the final Operation needs to be finished

- Float before production (GER Vorgriffszeit) = Number of working days as buffer between Order Start Date (GER Eckstarttermin) and production start date (GER Produktionsstarttermin). This buffer helps if components not being delivered on time

- Order Start Date (GER Eckstarttermin) = Date on which the FAUF can start earliest

- Queue Time (GER Wartezeit) = Time where the FAUF normally needs to wait at machine center before production can start

- Setup/ Machine/ Stripdown (GER Rüsten/ Bearbeitung/ Abrüsten) = Time based on values per operation, especially cycletime

- Wait Time (GER Liegezeit) = Time how Long the material needs to wait before next operation can start (i.e. cool down)

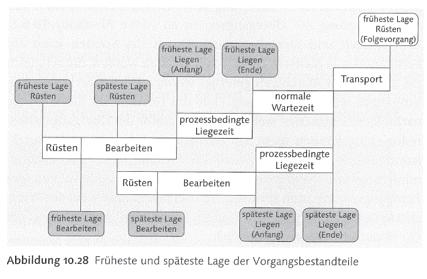

Another overview of Scheduling/ Timing:

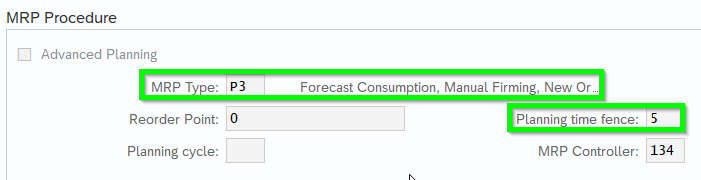

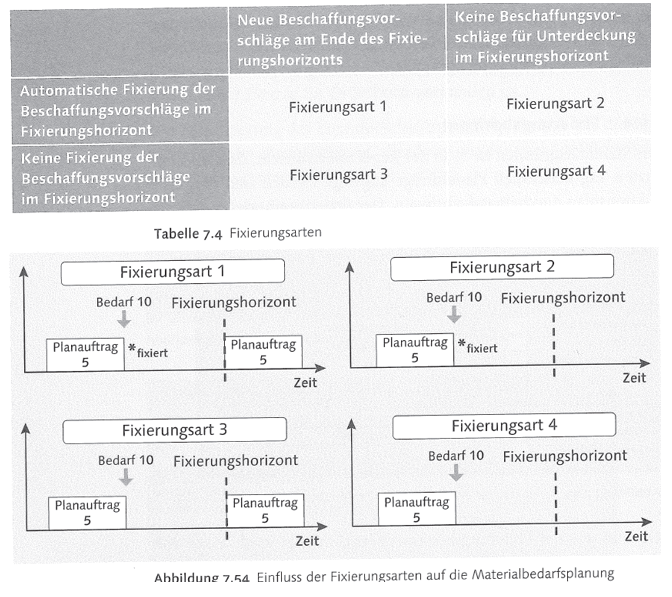

D. Planning time fence (GER Fixierungshorizont) MRP1

The planning time fence specifies a certain (production) period within which no automatic changes are to be made to the master plan. The planning time fence is maintained in workdays.

Here is an overview of the MRP types:

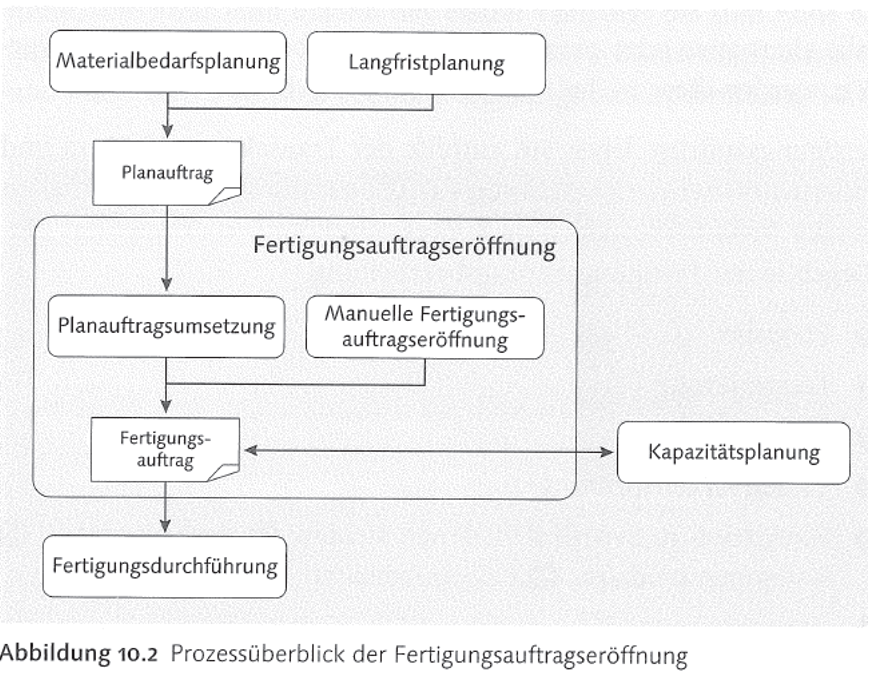

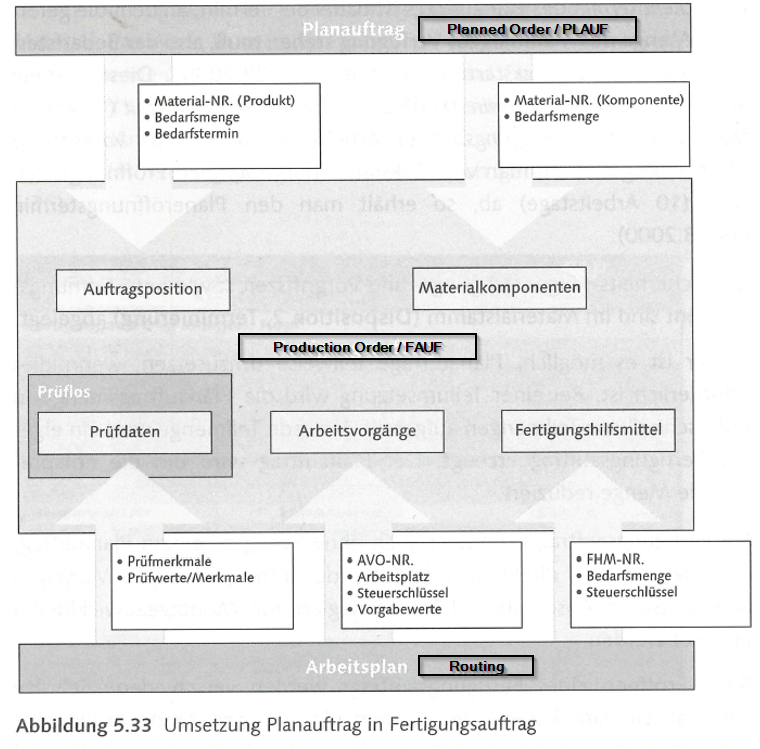

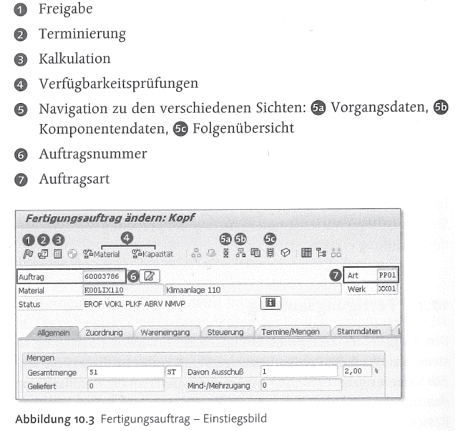

3. Production Order PLAUF/ FAUF

Planned Order (PLAUF) = SAP Element for Planning Horizont

Production Order (FAUF) = SAP Element for Production Control (short-term Horizont)

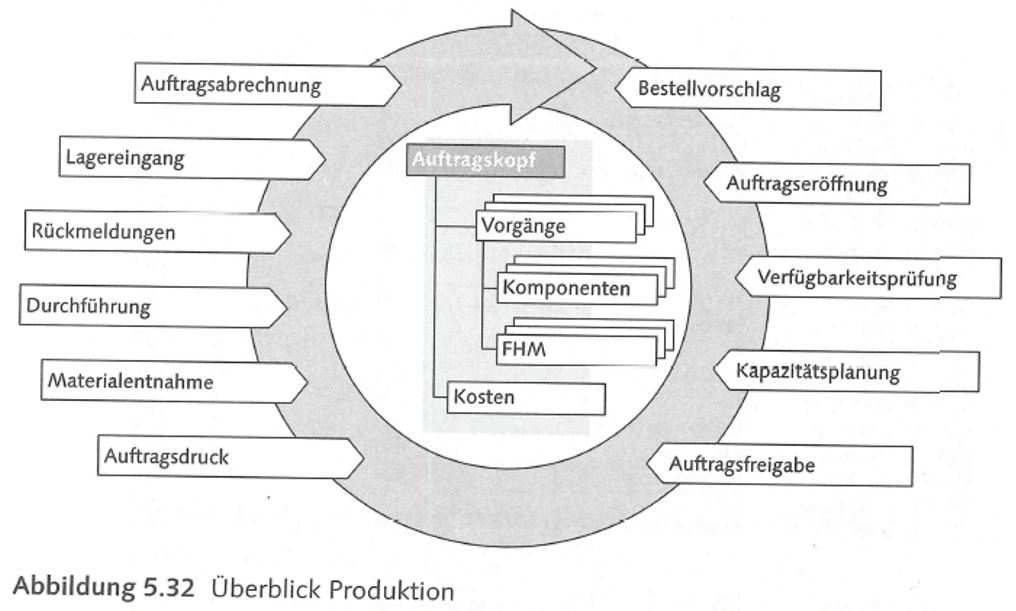

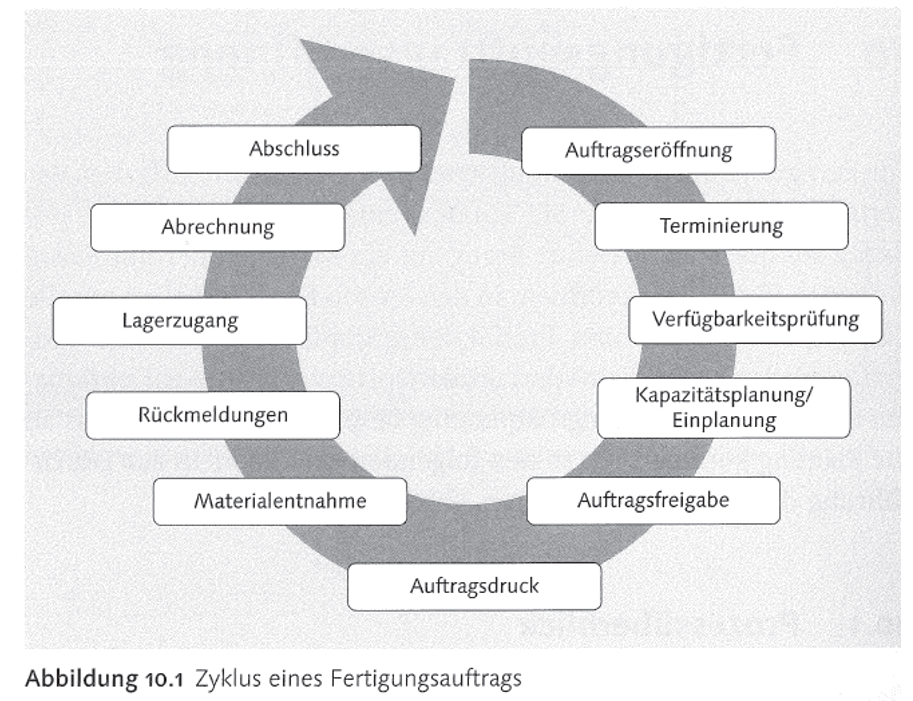

FAUF Cycle:

The components need to be available on Order Start Date:

The scheduling which determinates the Order End Date depends on the MRP Run Setting:

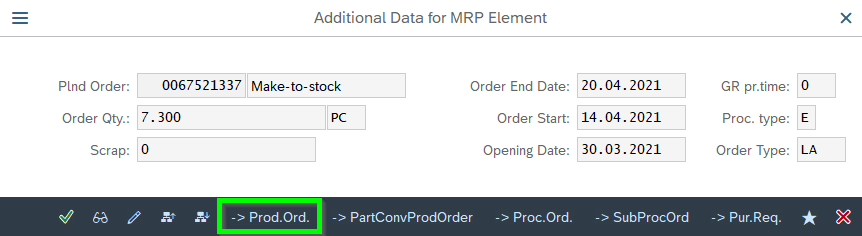

PLAUF –> FAUF: Following steps being done in the system: Look-up Routing, create reservations, create Purchase Requisitions or MM-Scheduling Lines, calculates planned costs etc.). Lead Time Scheduling (GER Durchlauf-terminierung) will always bei applied starting from Order Start (GER Ecktermine):

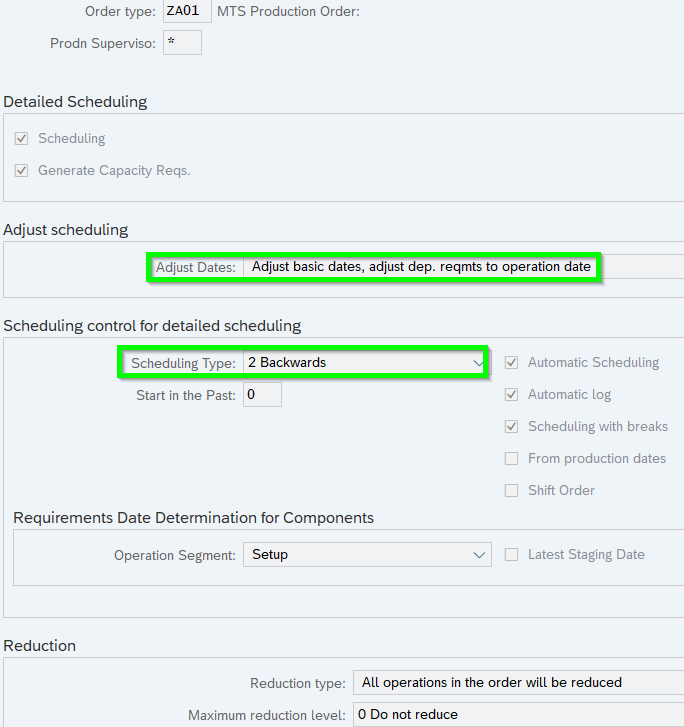

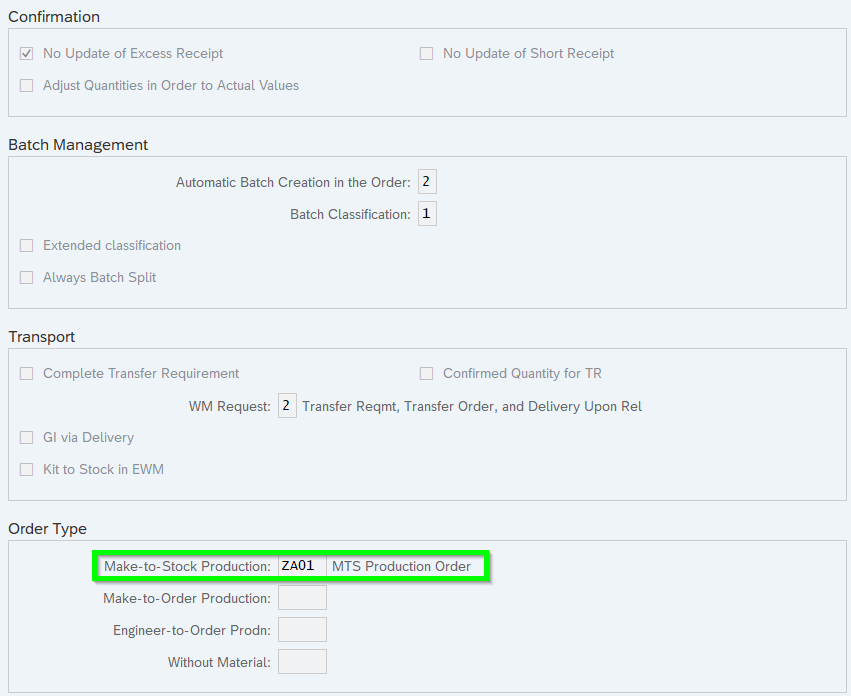

The Customizing of the FAUF type i.e. ZA01 can be found in OPU3: (GER Ecktermine anpassen, Sekundärbedarf auf Vorgangstermine)

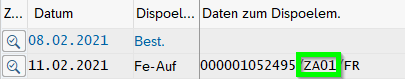

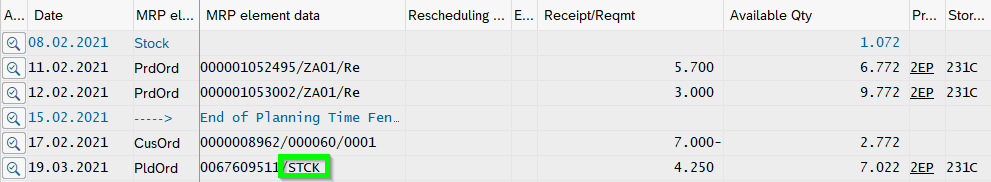

In the MD04 the type can been seen:

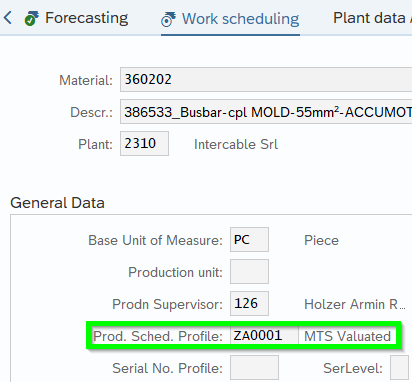

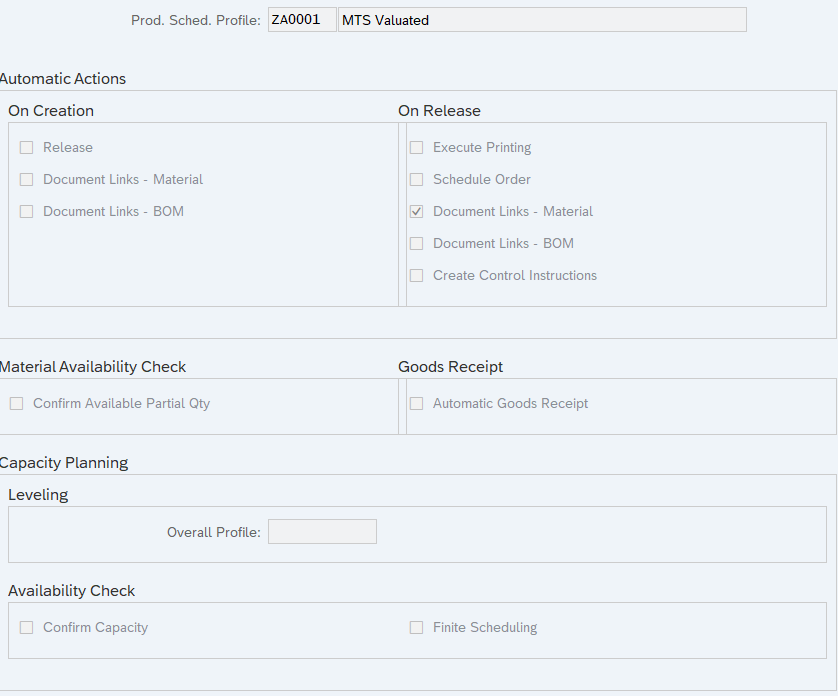

The Customizing of the PLAUF is OPKP. To set the right type for PLAUF master data-Work scheduling the Prod. Sched. Profile (GER Fertigungsprofil) needs to be maintained:

Customizing OPKP:

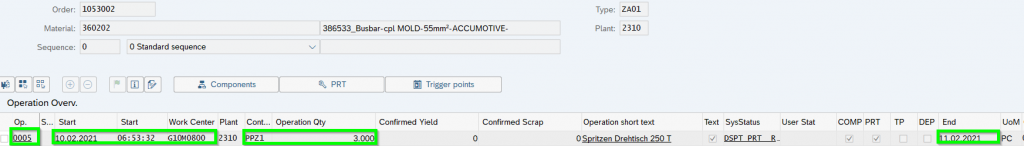

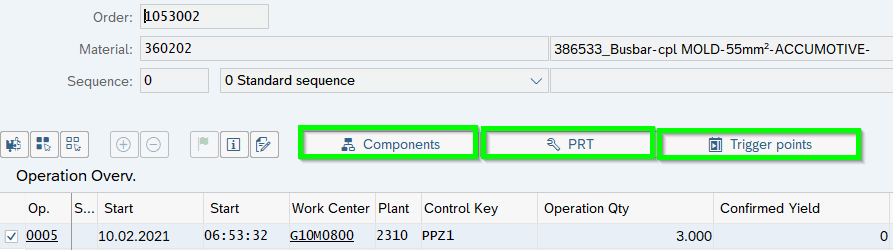

FAUF Operation Overview: The data of the Operation comes from the Routing but can be adjusted individually. Often a MES System (i.e. ProSes, Hydra) being used to determine the Start/ End Dates. The data transfer being monitored by SMQ1. Control Key (GER Steuerschlüssel) being maintained in Work Center (CR03).

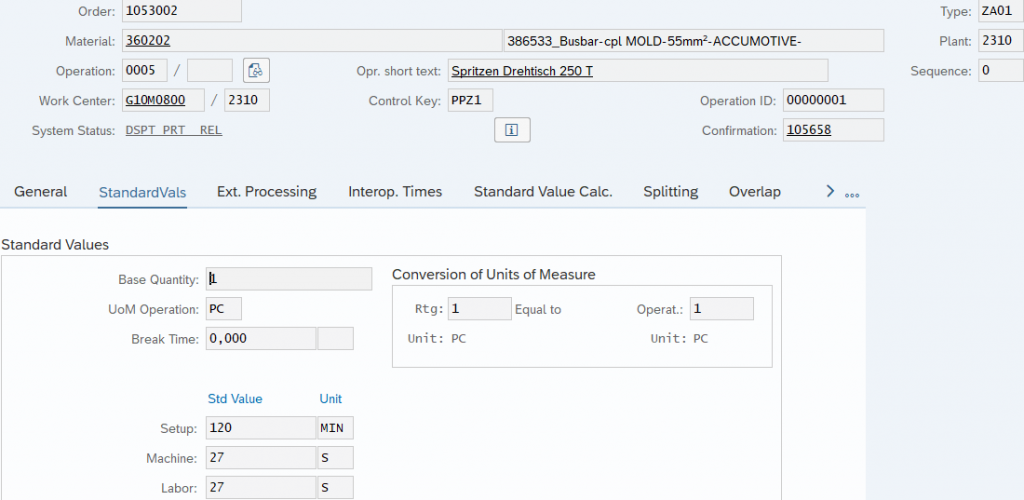

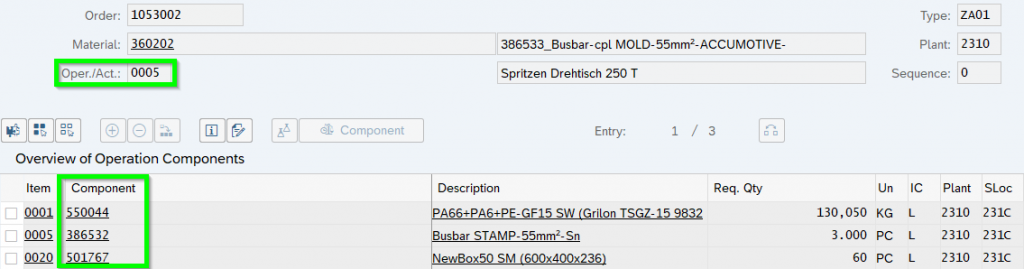

While double-click on Operation „0005“ further details can be retrieved:

In the same time components, PRT (Tools GER FHM=Fertigungshilfsmittel) or Trigger Points (GER Ereignispunkte) being assigned:

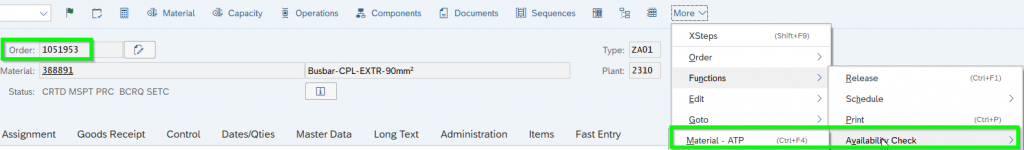

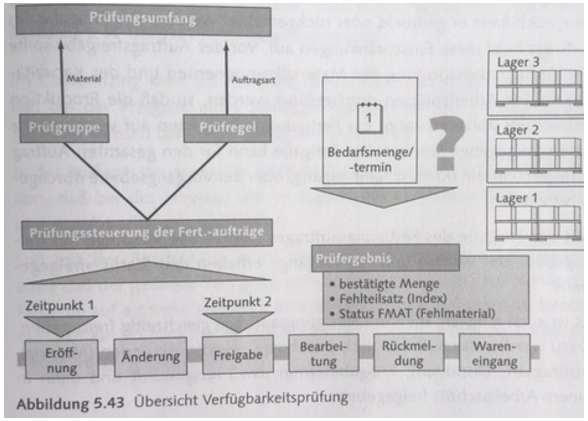

4. Available-To-Promise ATP (GER Verfügbarkeitsprüfung)

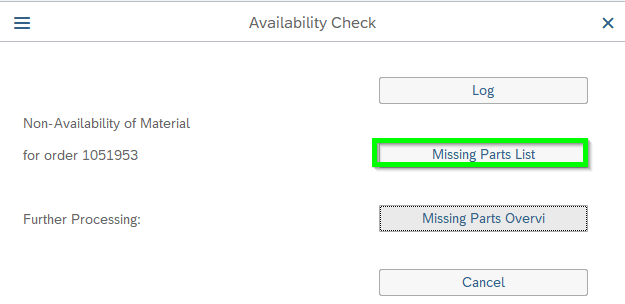

Before you release a FAUF the material availibility should be check. Go to CO02 of the FAUF and push STRG+F4:

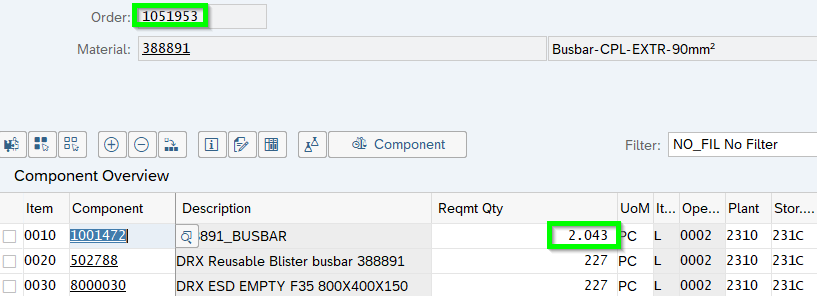

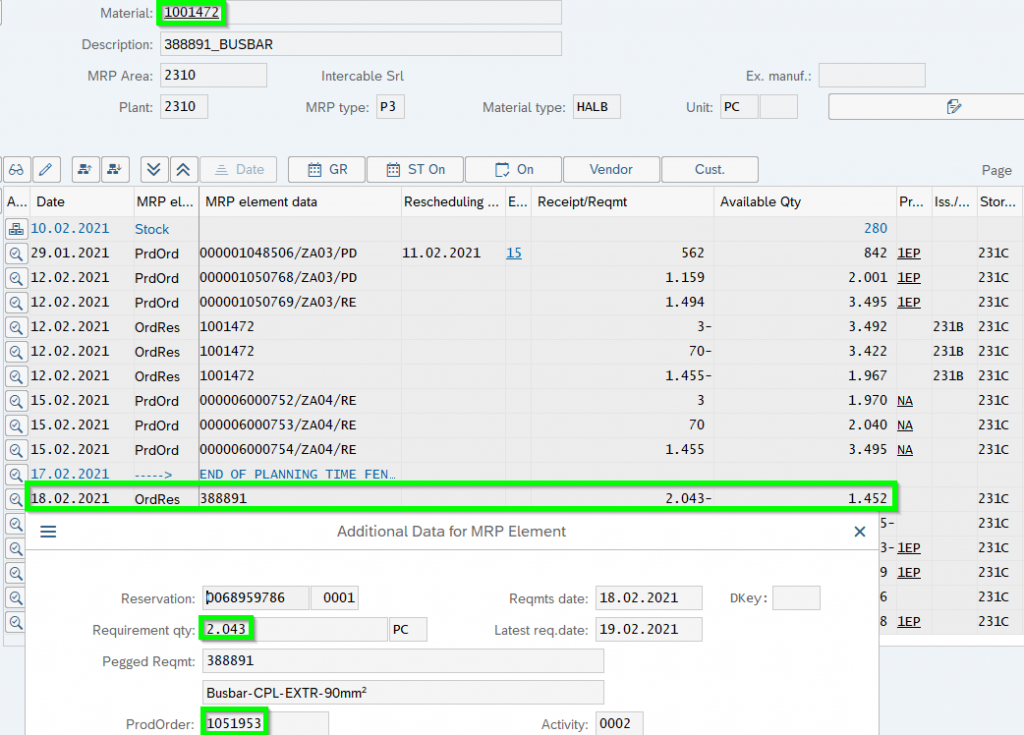

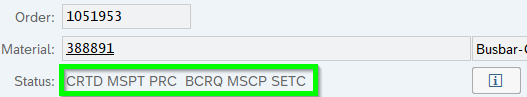

The ATP considers the current MD04 incl. SAP Elements. Let us check one component 1001472 where FAUF 1051953 needs 2.043 pcs. by 18.02.2021:

In the MD04 the stock is available hence no exception in ATP:

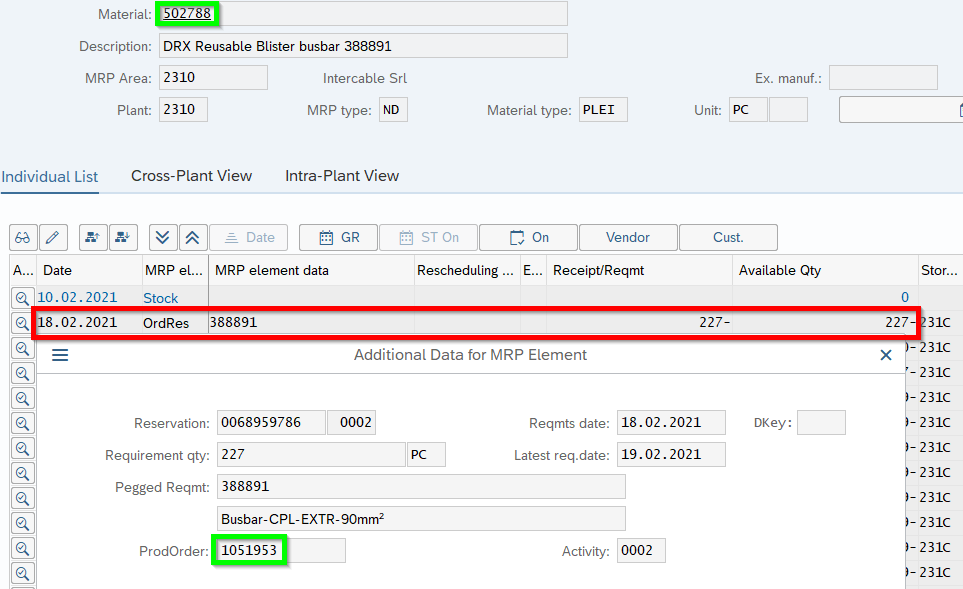

On the other hande for the blister 502788 no positive stock hence ATP exception:

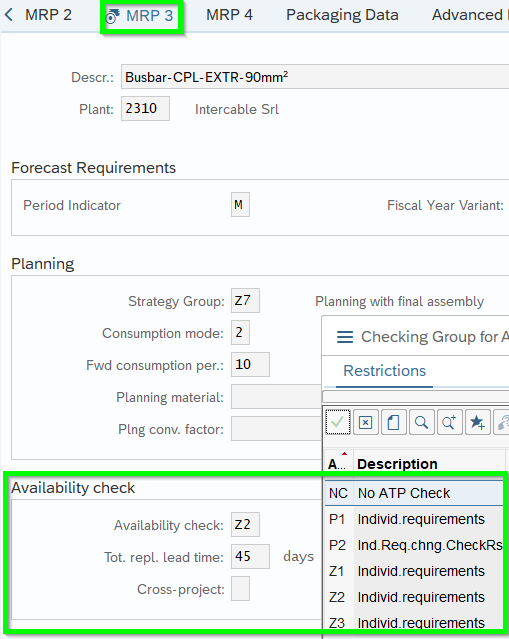

The Availability check is being set in Master Data-MRP3. In below’s example the total repl. lead time of 45 working days being considered with parameter Z2. Not only for ATP-Check of FAUF but also for customer orders this parameter being used:

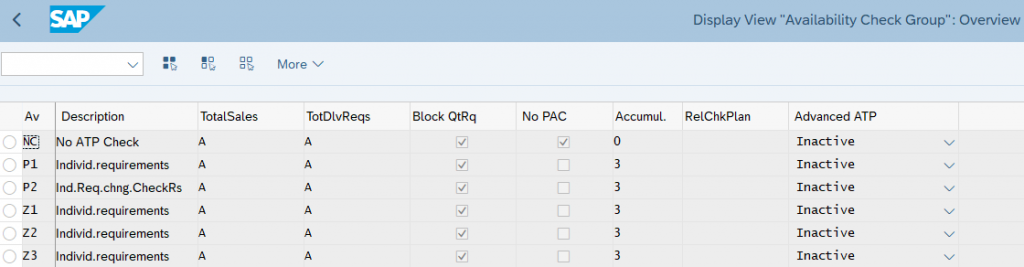

Customizing via OVZ2:

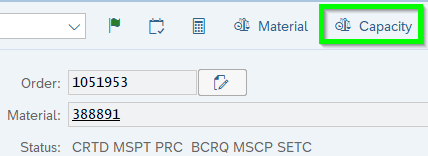

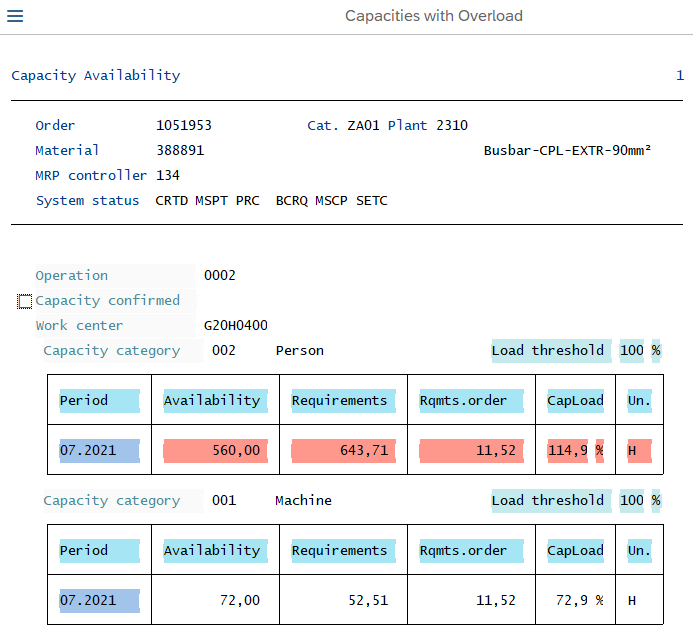

The other check is the Capacity. To use this functionality it needs to be decided where the finite capacity planning being done. In current SAP solution the functionality is not being used in ERP but in MES System so-called ProSes. Hence following screenshots give only a rough overview:

5. FAUF Release

Here an overview of the relevant steps until FAUF being released for production:

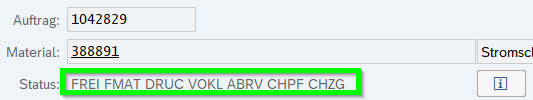

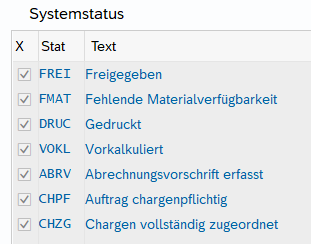

The different Status of FAUF are important. Here in English:

And in German:

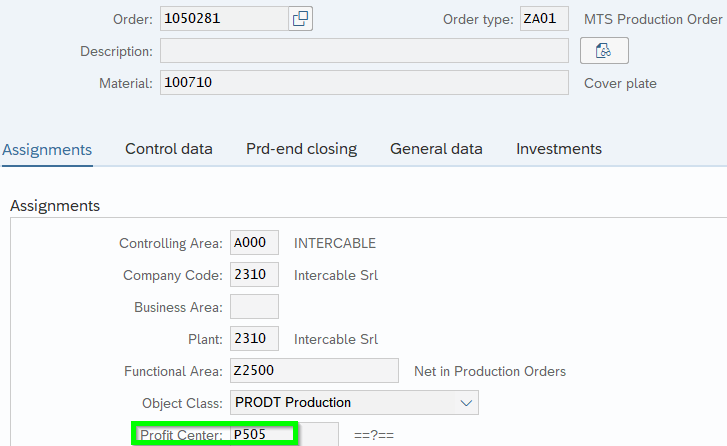

Not only the type of FAUF (i.e. ZA01) but also the FAUF number itsself can be used for quick understanding:

- 10#####: Serial production

- 20#####: Rework of send back material (GER Retoure)

- 30#####: Pre-Series

- 50#####: Sample

- 70#####: PPAP

- 90#####: Trial production (no despatch possible only inhouse)

In addition, certain Plant-specific Mat.Status (GER Werksspez. MatStatus) can be used to restrict/ trigger certain FAUF creation.

6. Capacity Management

A own chapter is being maintained. Please push button:

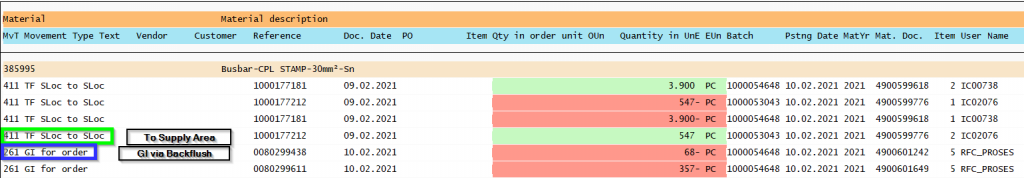

Capacity Management7. GI for FAUF Order (GER Warenausgangsbearbeitung FAUF) Movement Type 261

Normally two major process types being used:

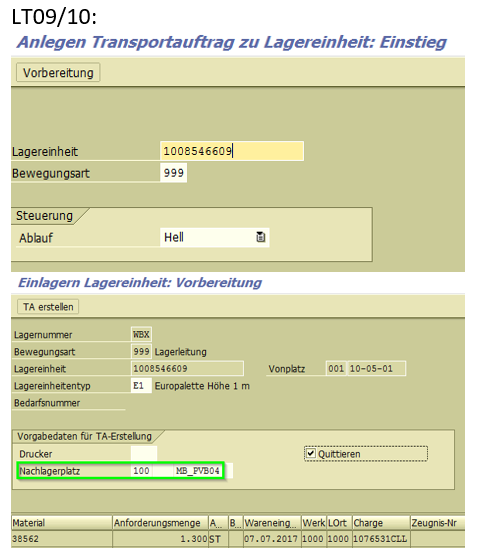

- With Handling Units without EWM: Transport Orders (LT09/10) to Supply Area (GER Produktionsversorgungsbereich PVB)

- With EWM (see chapter Logistics). Backflush will be explained later since Confirmation need to occur before:

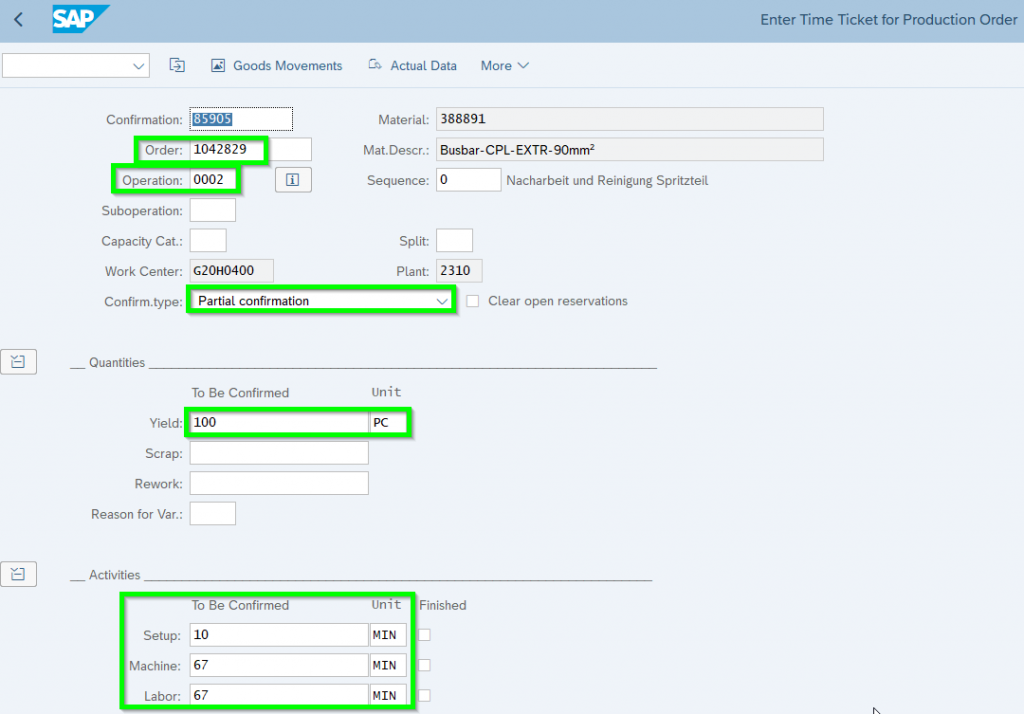

8. Confirmations (GER Rückmeldungen) CO11N/ CO14

If a material being produced or an operation being done this information needs to be given to FAUF (so-called Confirmation (GER Rückmeldungen)). Confirmations can only be done if FAUF being released!

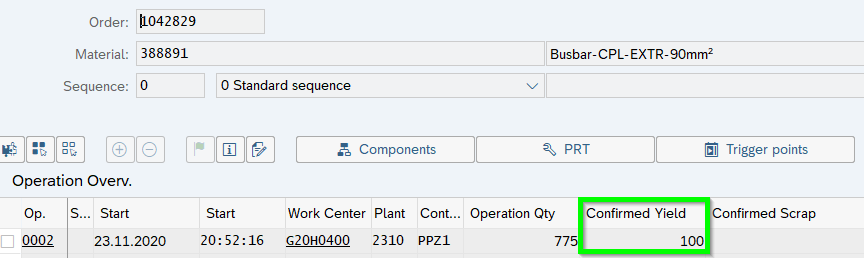

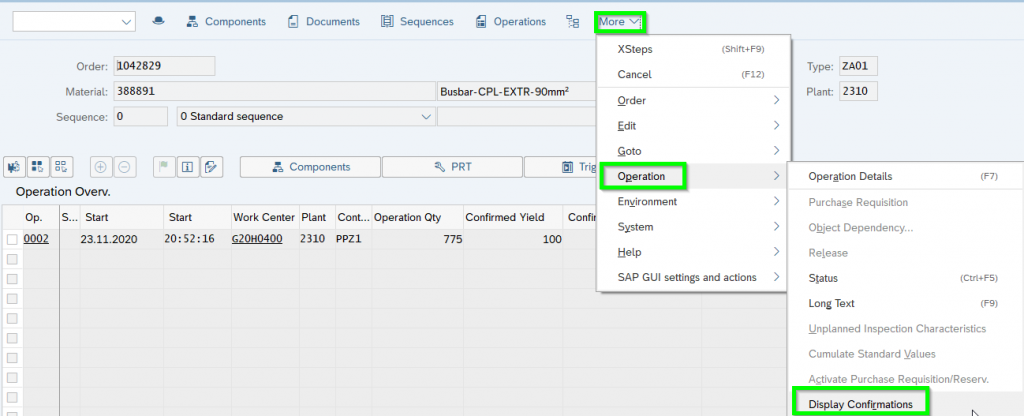

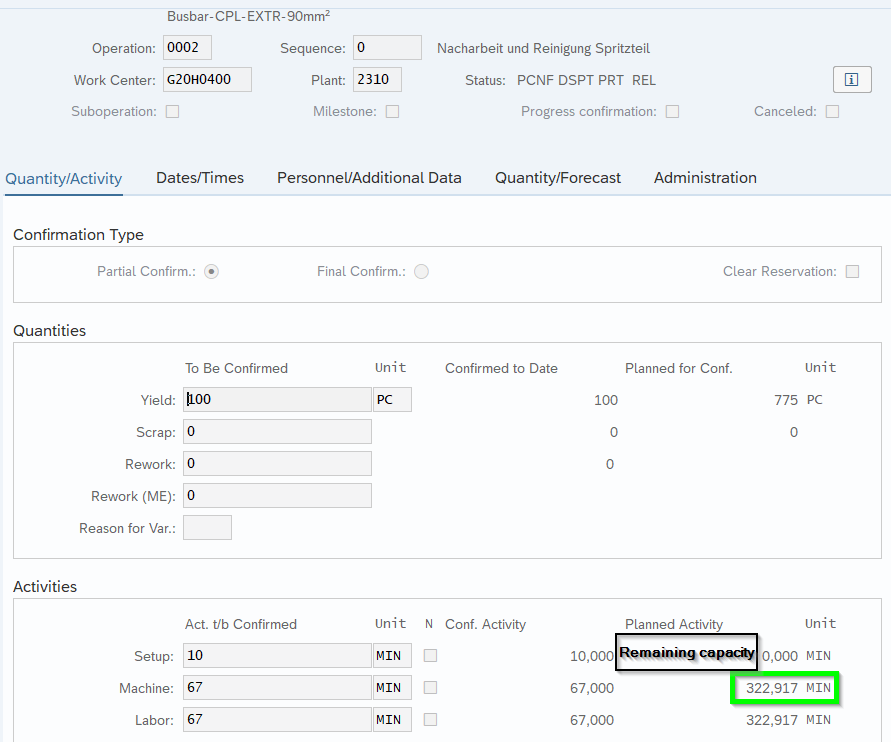

In a second step other operational steps being triggered (i.e. as-is costs; reduction of capacity, backflush). Normally such a confirmation being done via MES System. Here is an example for a manual confirmation via CO11N:

Consequently the confirmation being displayed in the FAUF and the capacity is reduced accordingly:

The single confirmations can be accessed via following path:

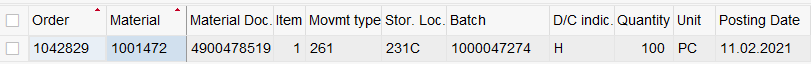

Since Backflush is set the GI for FAUF Order being done simultaneously:

Cancellation of a confirmation being done via CO13. All booking will be removed as well (262 movement type).

9. Processing of Error Records from backflushing (GER Nachbearbeitung von Fehlersätzen aus retrograde Warenbewegungen) COGI

The process Backflush offers a good automatic consumption of components/ stock. Next step the MRP considers the reduced stock and creates new demand. On the other hand it can be risky if the Backflush fails but physically components being consumed. The stock still exist in the system hence MRP will not create new demand. Risk of out-of-stock items are given.

For this special error management a separate internet page exists:

COGI and SMQ2The processing of Error Records COGI should be cleared daily.

9. GR for order (GER Wareneingang aus FAUF)

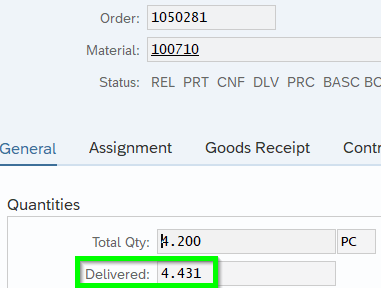

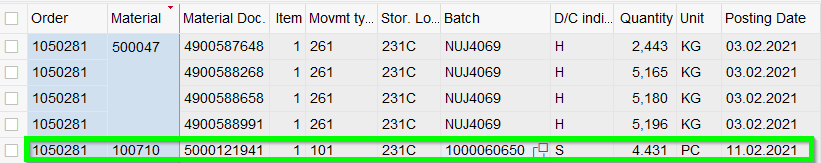

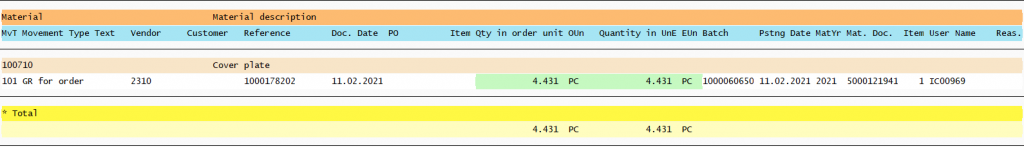

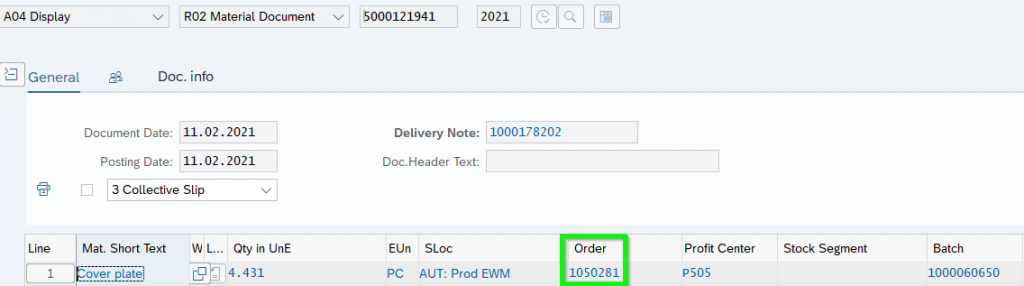

Depending on the progress of the production stock of the produced item being created out of FAUF. Those can be retrieved via CO03:

Or from there to documented goods movements:

Another options is MB51 with movement type 101:

Then double-click:

10. BASC-Batch assignment complete (GER TABG-FAUF Technisch Abgeschlossen

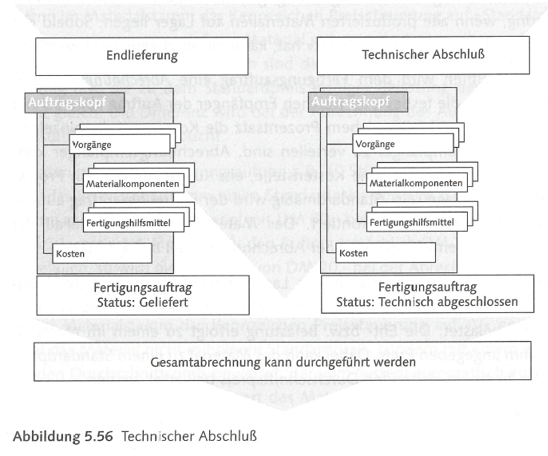

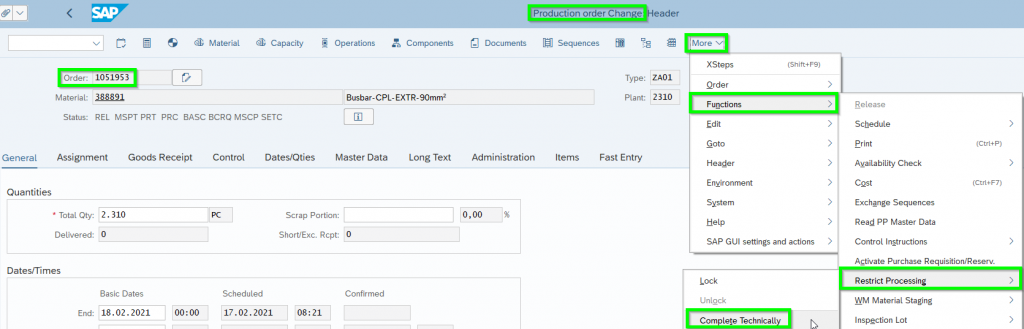

Each production order FAUF should be receive Status BASC (GER TABG). Such a FAUF will no more create any demand in the System. Following overview helps to understand:

To proceed use CO02:

11. FAUF-Clearance (GER FAUF-Abrechnung) KO03

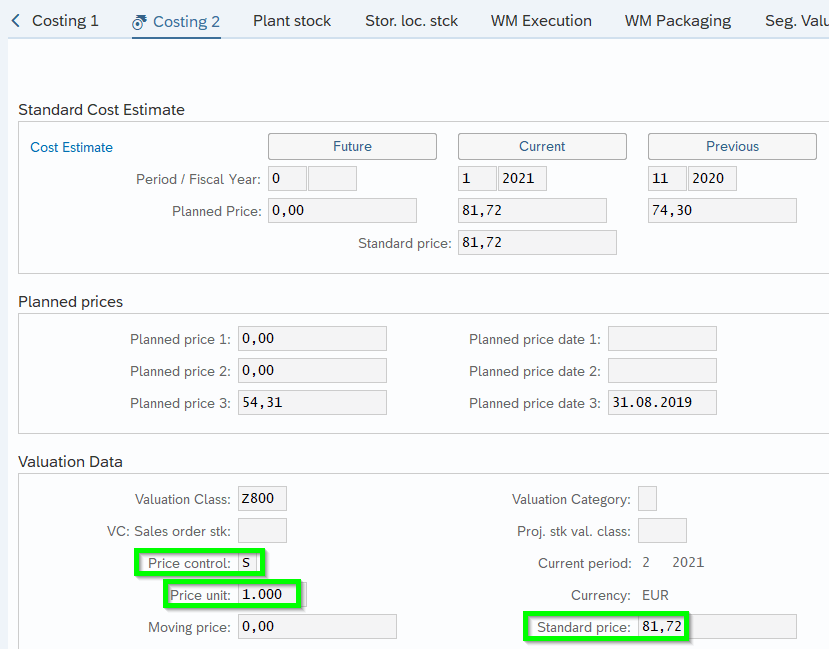

All FAUF relevant costs like material and workers will be collected (Charge-Side GER Belastungsseite). The credit (GER Entlastung) is being carried out via the Goods Receiving against Order (Movement type 101) (see Point 9) via Standard Price. Those Costs must be carried out after the FAUF received BASC/ TABG.

KO03:

The Standard Price can be found via MM03-Cost 2:

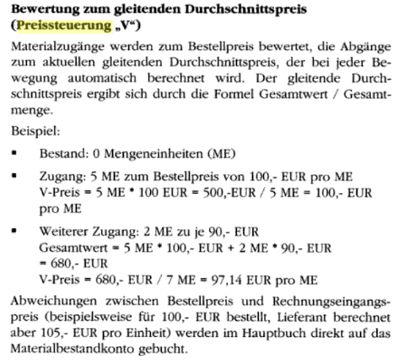

Excursus: Moving average Price (GER Gleitender Durchschnitspreis) = V

If selected the System calculates it automatically: Gesamtwert des Materialbestandskontos durch die Gesamtmenge der an allen Lagerorten befindlichen Materialien geteilt wird: