A General Overview of Business Process in Sales and Distribution can be found in Point 3:

SD SCM600Dependent requirements are being created by real orders. Mostly real orders being created by customer Sales Orders or Scheduling Agreements = Call-Offs.

1. Sales order (GER KunAuf) – VA01

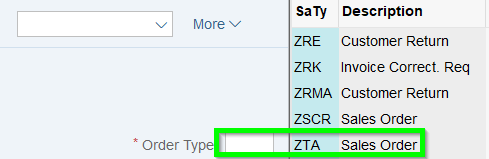

- Must field is the Order Type (Table VBAK Field AUART). The SAP standard offers already many options but normally each client customizes the Sales Orders according its needs (normally starting with Z). Examples: ZPRO = Project Order/ ZTA = Sales Orders

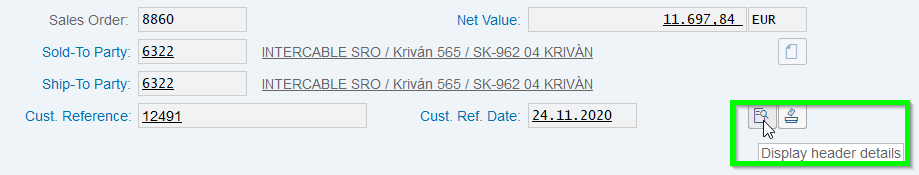

- If you like to retrieve the Order Type via an existing Sales Order (VA03) press button „Display header details“. In the folder „Sales“ the Order Type is listed up:

- Major data like Sales Order number is created automatically after saving. Sold-To Party/ Ship-To Party/ Cust. Reference and Cust. Ref. Date needs to be entered. Normally the Cust. Reference is the Purchase Order from customers ERP System.

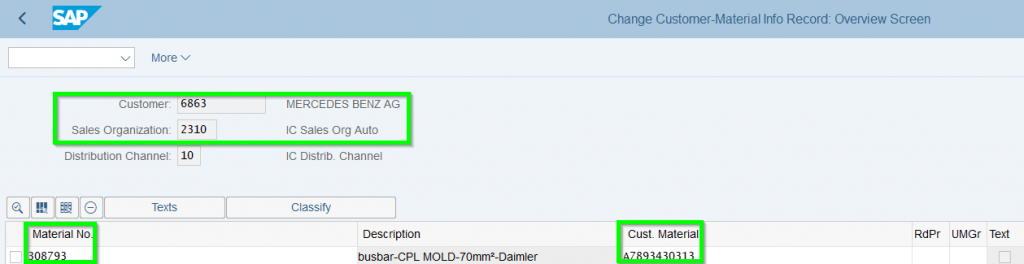

- The Customer material number is an important data field since it matches the future deliveries with the customers ERP. Here the „Customer-material Info Record“ via VD51 must be maintained. To retrieve relevant data use VD59.

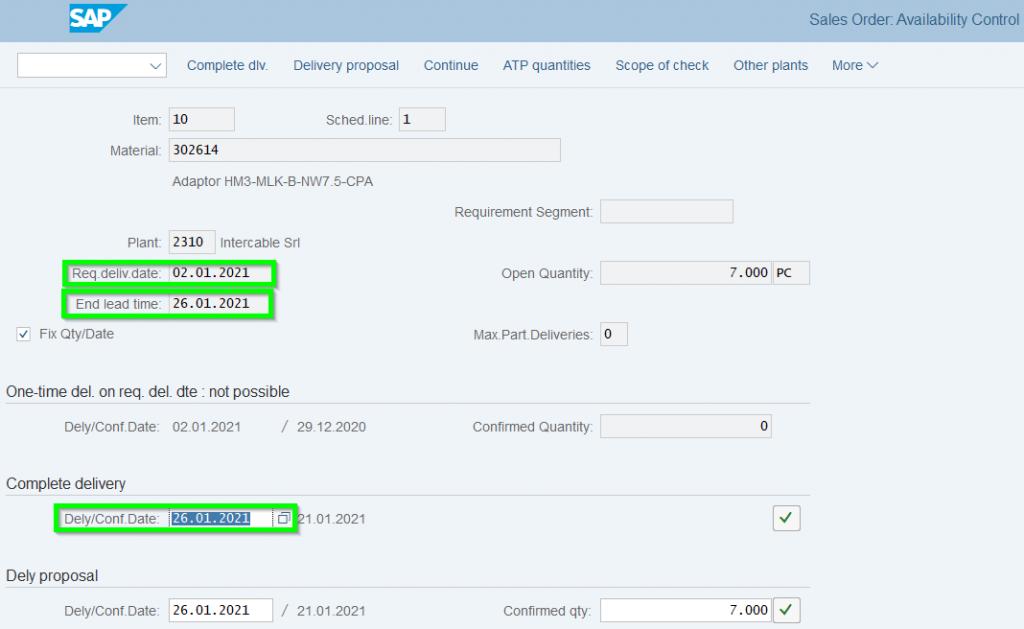

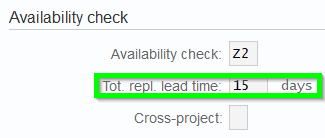

- Then the relevant items with qty. and the requested goods receiving date of the customer. Normally the „Tot. rep. lead time“ in MRP3 is activated, so the System calculates the „Dely/Conf. Date“:

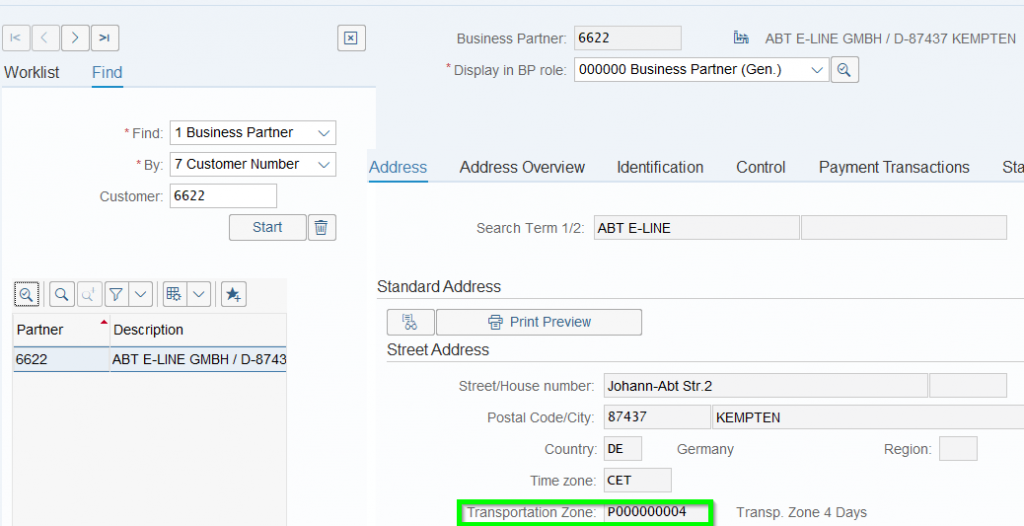

- The route/ transportation zone is normally maintained on master data Business Partner (BP)

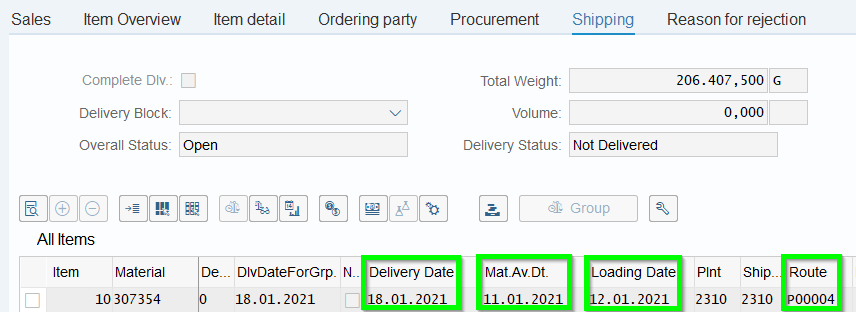

- In the Sales Order the relevant backward calculation can be found in Folder „Shipping“:

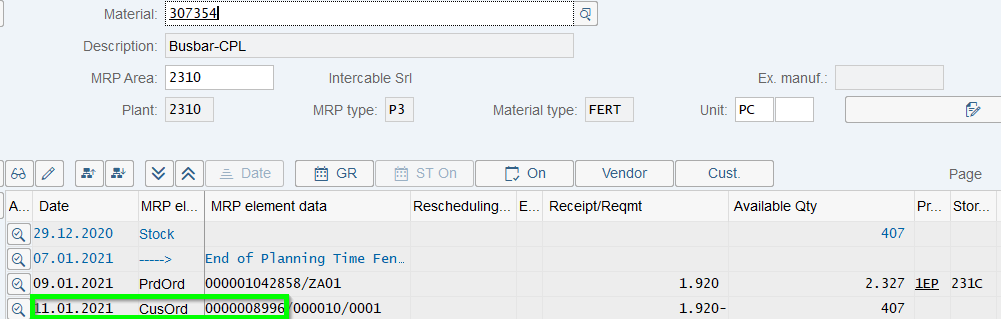

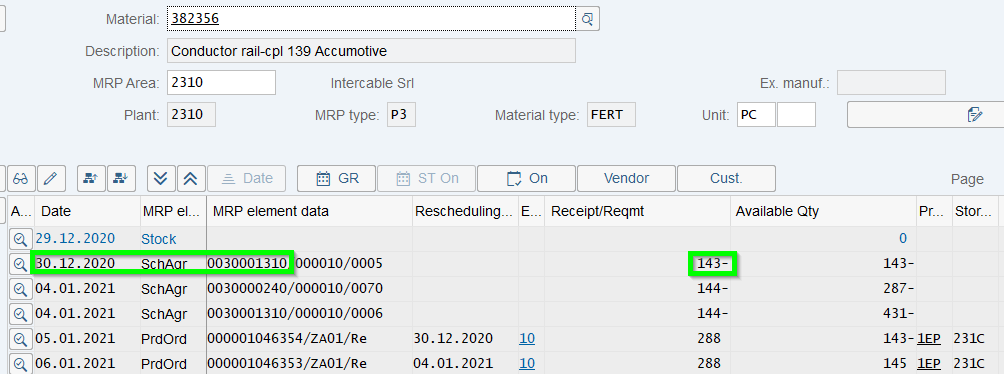

- Consequently the Sales Order creates a dependent requirement in the MD04 based on 11.01.2021:

——————————————————————————————————————–

2. Scheduling Agreement (GER LiefPl) – VA31

- In the Automotive sector the Scheduling Agreement is the normal method to create dependent demand. Here the complex topic of Electronic Data Interchange (EDI) being referred later.

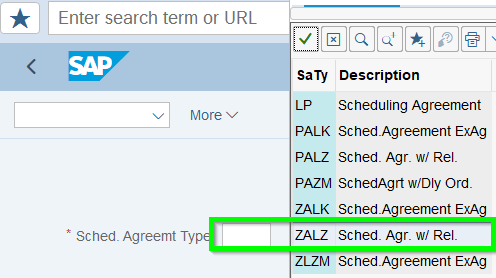

- Similar like Sales Order a must field is the „Sched. Agreemt Type“ (same Table like Sales Orders VBAK field AUART):

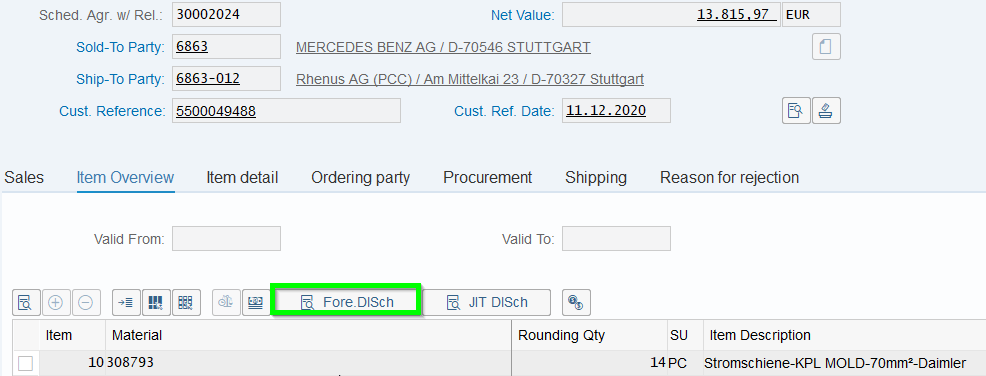

- Data entries is similiar like Sales Orders, except that volumes being maintained as „Fore.DiSch“:

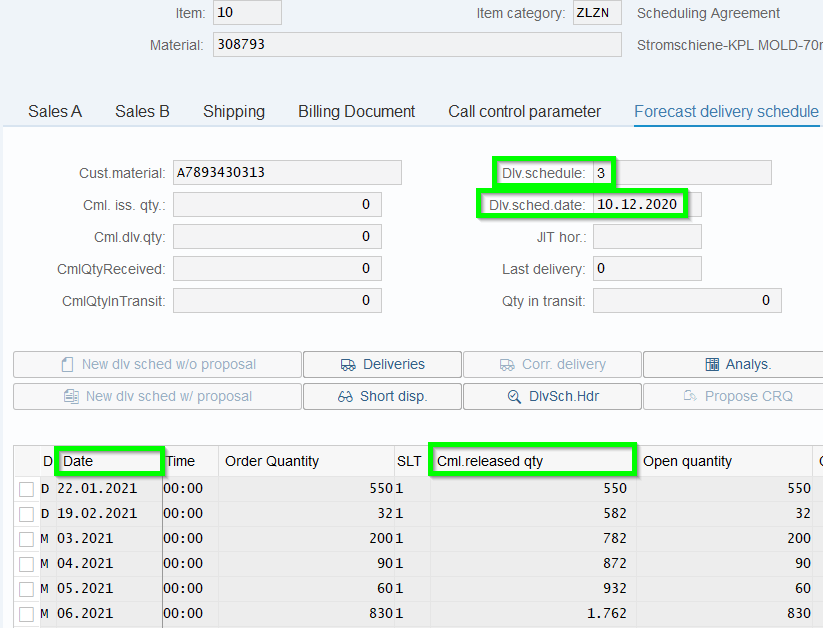

- The biggest benefit is that the customer offers a forecast. Depending on the customer the forecast can be 6 to 24 months and sometimes even more. The volume and the date is given as well. In addition the important cumulative qty. (GER Fortschrittszahl FZ) being created by the SAP System based on the single order qty:

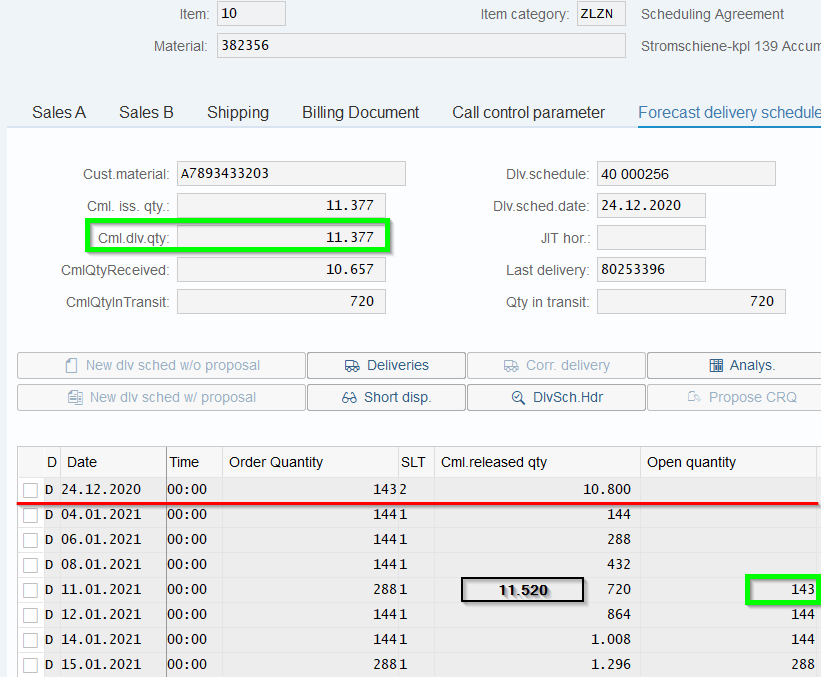

- The open qty. are being calculated as follows: Cumulative demand or release qty. ./. cumulative delivery qty. In our example 11.520 ./. 11.377 = open 143 from 11.01.2021

- The Cumulative delivery qty. is created by the sum of the deliveries in each period, e.g. period 00.2021 (table S073 field LIFFZ with period SPBUP)

- The Cumulativ demand or release qty. is the sum of all scheduling lines (table VBEP field WMENG)

- Normal SAP customizing starts the cumulative calculation always with each new year again (see data below the red line). A so-called cum. figure adjustment is necessary over the new year, especially when the customer is not setting its cum. figure to zero

- Routing sets the dates in MD04 similar like Sales Order

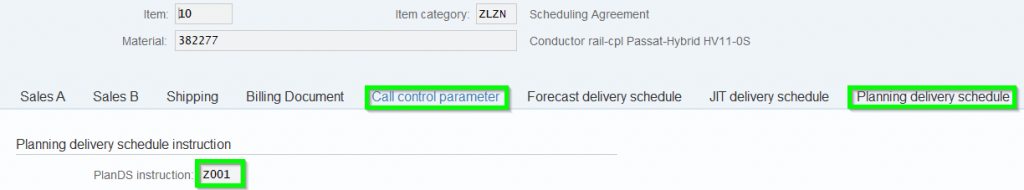

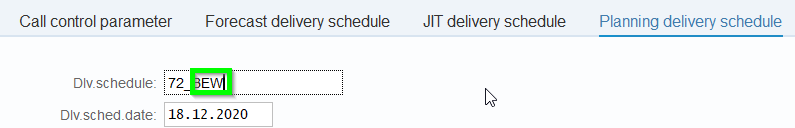

- Setting Parameter „PlanDS instruction“ (GER Abruferstellunsgprofil) in Folder Call Control Parameter offers the possibility to create a Planning delivery schedule. Via Customizing a lot of features can be created. In our case the weekly demand given by customer call-off is set to the specific working date of the given week

- The Option Planning delivery schedule (GER PLAB) is necessary if manual adjustments in comparison to customer call-off are necessary. For example adjusted volumes or dates or change over of demand to new material numbers (Technical Change). In this case it is recommend to add initials after call-off number to see that manual changes be made

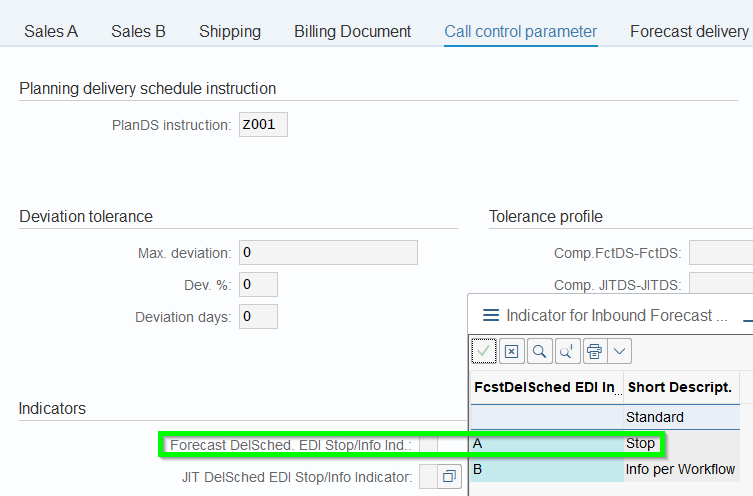

- Usually Jobs activate new scheduling lines/ call-offs in the night and then overwrite the latest scheduling line or Planning delivery schedule (GER PLAB). To avoid this overwriting EDI stop can be set so during working times the new EDI’s can be compared and manually processed. In this case also manual maintained PLAB needs to be adjusted again.

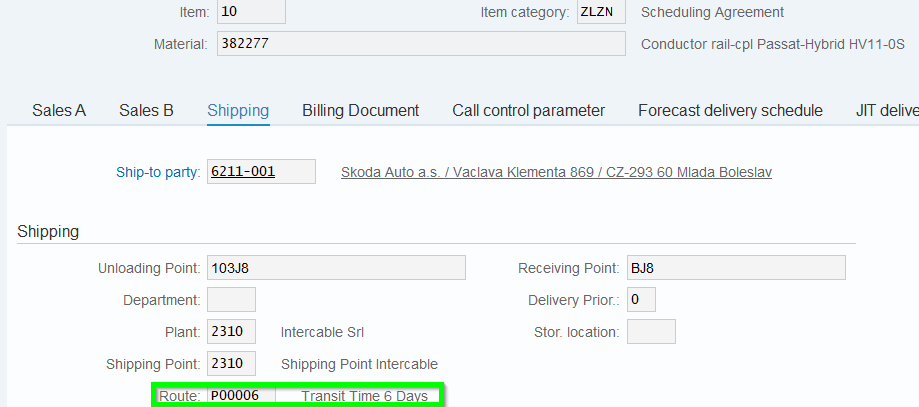

- Route can be retrieved from Folder Shipping:

——————————————————————————————————————–

3. Sales order / Schedule Lines monitoring (VL10E) –> create shipments

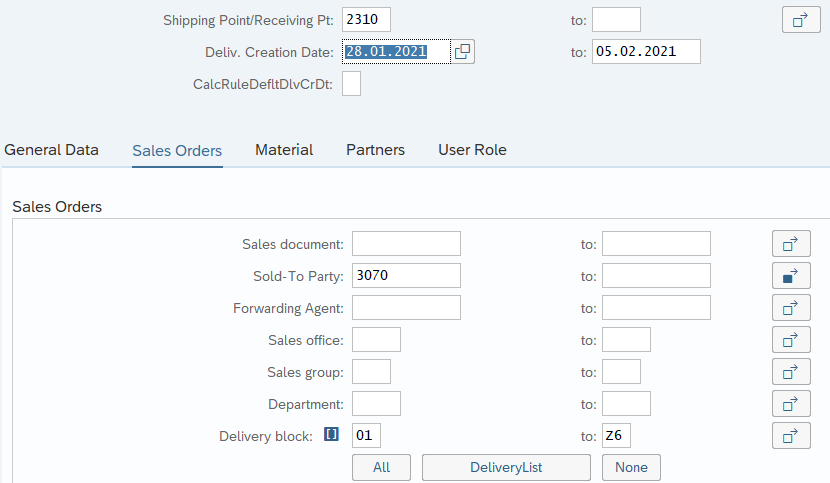

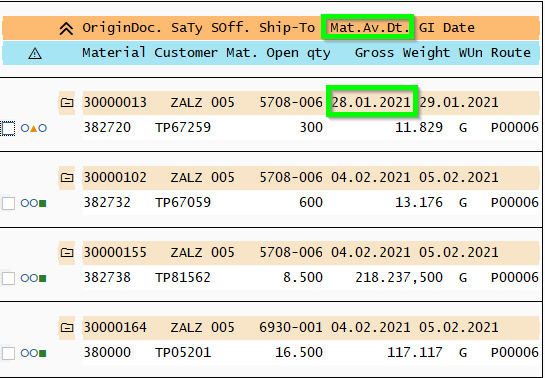

The transaction VL10E gives the Sales Office the monitor function to select open customer demand and create shipments if stock being available:

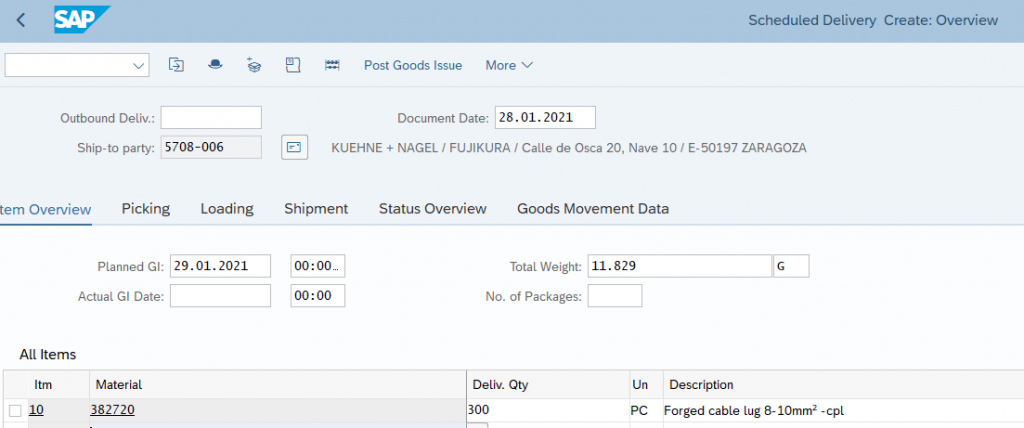

Following activities Due list for shipping is created. The report was taken on 28.01.2021 so the traffic light is yellow. Today the shipment should be created to despatch it on GI Date 29.01.2021:

By ticking the box and enter „Dialog“ button you open the „Create shipment“ dialog (VL01N) to create shipment. So the despatch operators can start preparing their despatch activities:

——————————————————————————————————————–

4. Call-Off Analysis

Please push button to go to the Call-Off Analysis

Call-Off Analysis5. SAP Training Course SCM600 SD in German

Following file is a comprehension of the SAP Training Course SCM600 in German: