1. Material Master Data (MM01)

- Material Classification (GER Materialart) like finished goods, semi-finished goods, raw material etc.

- MRP type-MRP1 (GER Dispositionsmerkmal) like forecast consumption or reorder point Planning

- Lot size data-MRP 1 (GER Losgrößenverfahren)

- Procurement type-MRP 2 (GER Beschaffungsart) inhouse or external procurement

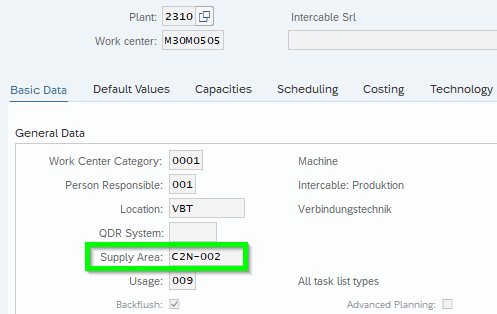

- Backflush-MRP2 (GER retrograde Entnahme) can be set. The supply area (GER Produktionsversorgungsbereich PVB) where backflush being done is being set in work Center:

- Scheduling-MRP 2 (GER Horizontschlüssel) controls the scheduling/ termination of PLAUF/ FAUF:

- Consumption mode-MRP3 (GER Verrechnungsmodus) Backward/ Forward consumption (GER Rückwärts-/ Vorwärtsverrechnung)

- View Work scheduling (GER Arbeitsvorbereitungssicht) needs to be maintained to match routing with materials via production versions. In Addition the Prod. Sched. Profile (GER Fertigungsprofil) needs to be maintained so correct set up of PLAUF being done (Customizing OPKP)

- Valuation Class-Accounting 1 (GER Bewertungsklasse) so Posting being done on certain G/L accounts (GER Sachkonten)

- Price Control indicator-Accounting 1 (GER Preissteuerung) to set fixed standard Price or moving average price

- With Qty. Structure-Costing 1 to set if material number will be written to the cost element itemization (GER mit oder ohne Mengengerüst)

- View Costing 2:

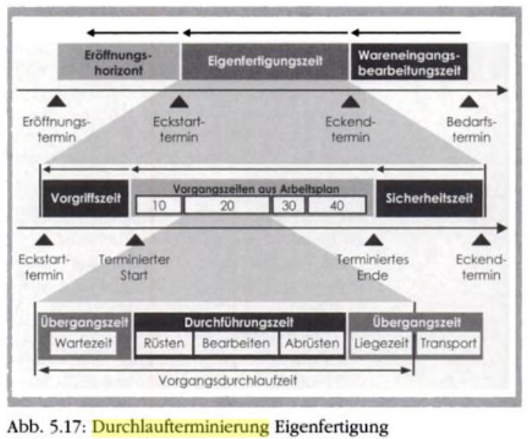

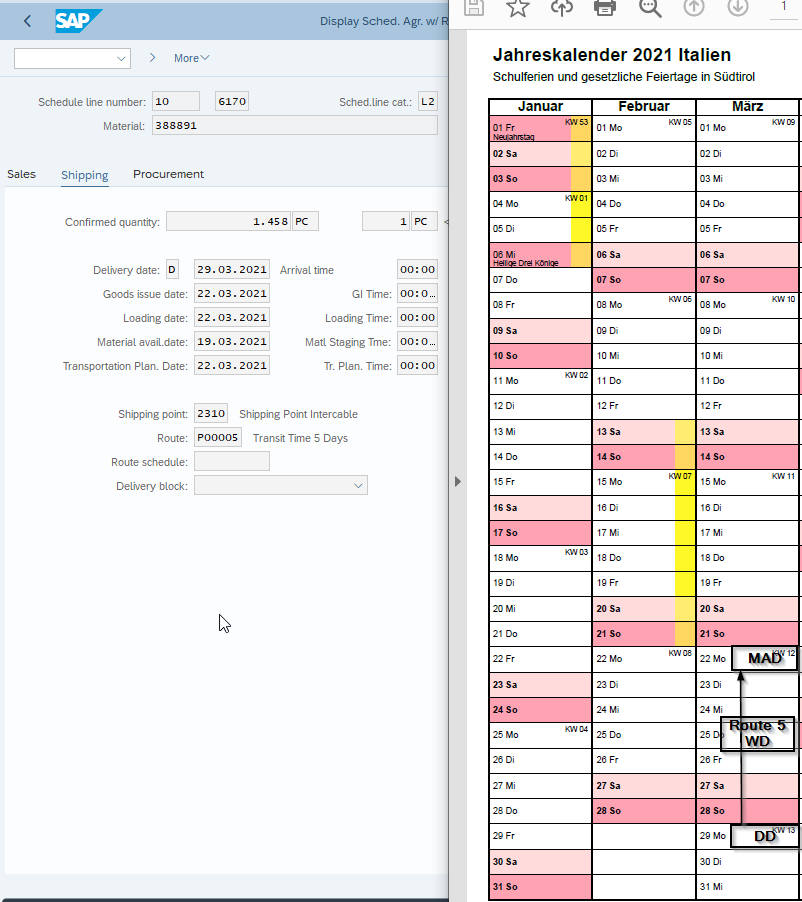

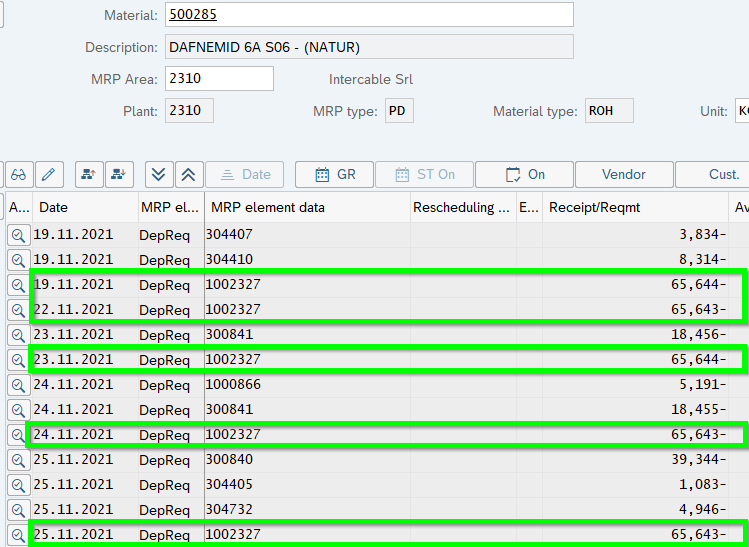

Example how PLAUF Basic End Dates (GER Ecktermine Ende):

The PLAUF „Basic End Date“ is driven by the „material avail. date“ of customer order/ scheduling agreement. The route is most important, usually being taken from the „transportation zone“ of the „Ship-to-Party“. The transportation zone being maintained in BP-FLCU01 Customer in the Folder „Adress“:

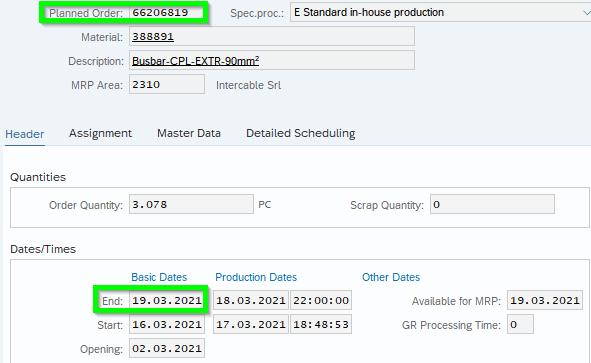

The respective PLAUF takes the „Basic Date End“ 19.03.2021 for its backward calculation. It is recommended that the customer maintains a lot size according our recommendation within its scheduling lines:

2. Bill of Material (CS01)

- BoM Header applies to all knock-down levels e.g. base quantity. Different base units (e.g. KG to G) can cause problems between the different SAP modules (e.g. ERP with EWM). Therefore it is recommended to maintain Base quantity of 1.000 PCs.

- BoM Position applies only to the relevant component. Normally the item category is L (stock item GER Lagerposition).

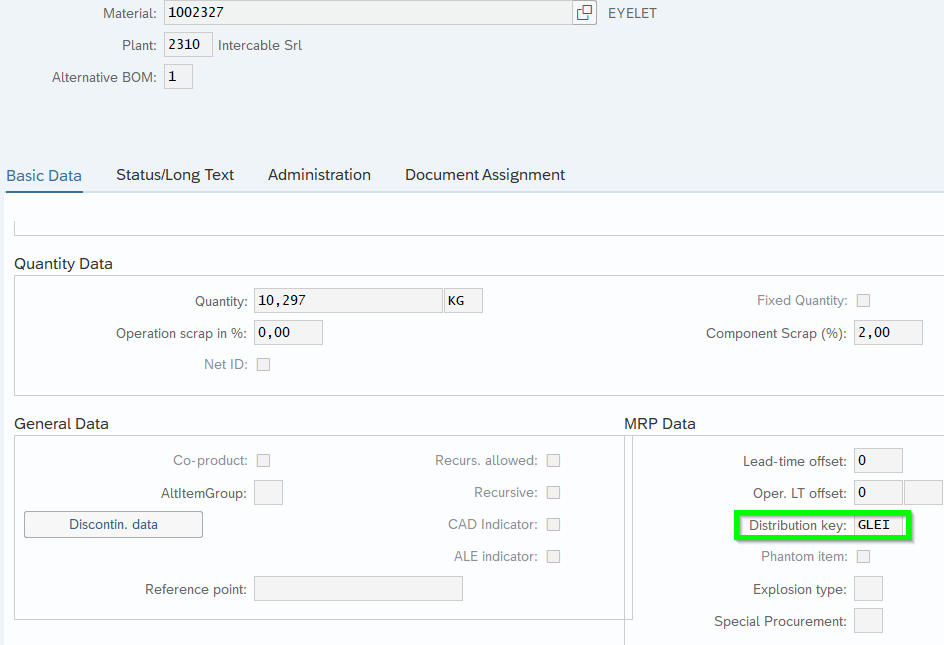

- Distribution key (GER Verteilungsschlüssel GLEI) determines the split to be used for distributing the run schedule quantity (into partial quantities) over the validity period of PLAUF/FAUF.

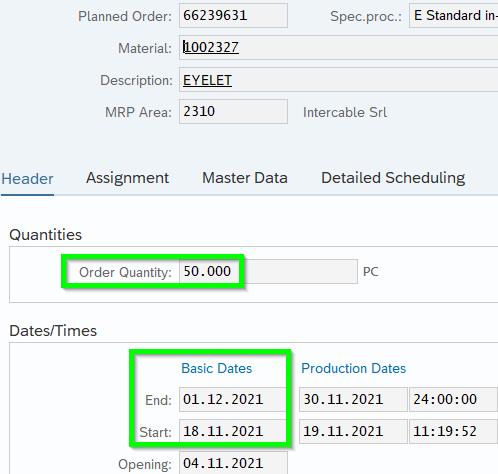

The PLAUF takes nearly 2 weeks to be produced:

The supply of sub-component will now being supplied not on one time but daily during the two weeks of PLAUF. In case of PLAUF on component level also those will be levelled out and capacity will be spread.

3. Work Center (CR01)

- Work Center can be single machines, set of machines, workers, worker groups, production lines etc.

- Customizing Work Center Category (OP40):

In the second level the Work Center Category can be applied to certain routings (GER Arbeitsplänen):

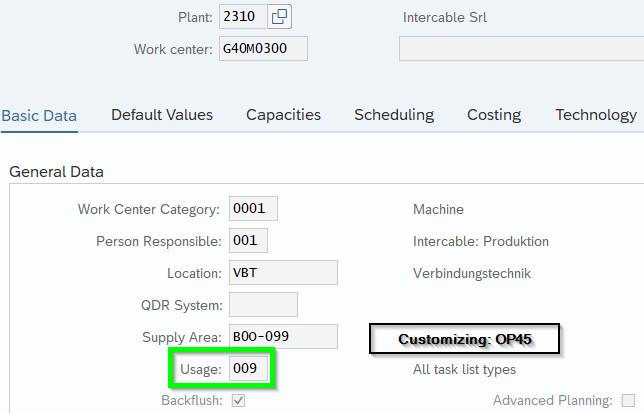

Customizing of mandatory field Usage in CR03 use OP45:

Usage 009 can be assigned to several different routing types (i.e. N Routing):

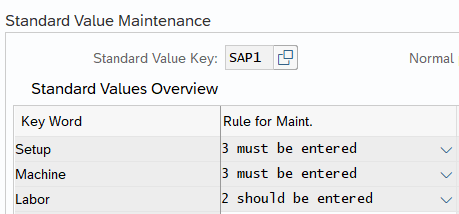

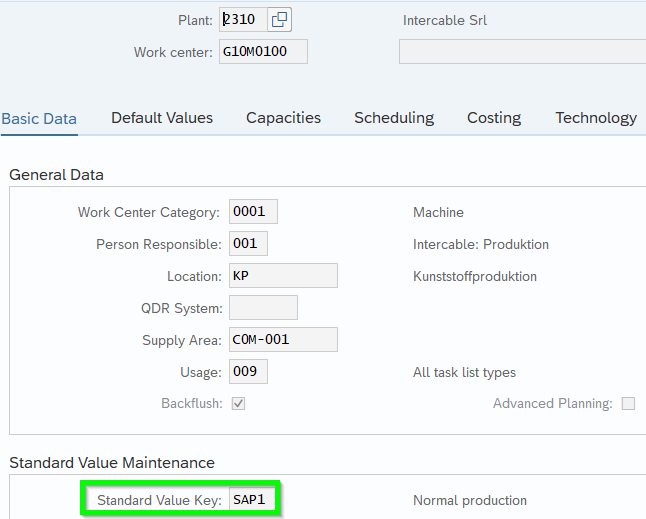

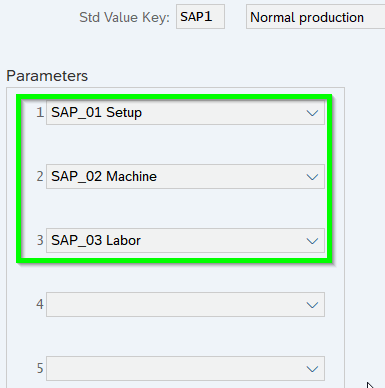

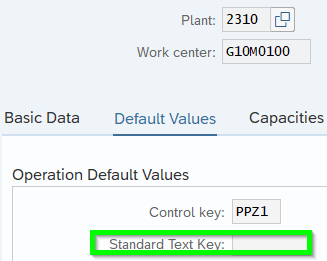

- Basic Data: Work Center Category like machine or worker, Supply area (GER Produktionsversorgungsbereich PVB) for backflushing, Usage i.e. normal Routing or maintenance, Standard Value Key (GER Vorgabe-wertschlüssel) defining and giving a Dimension (i.e. time or area) to one of up to six Standard values:

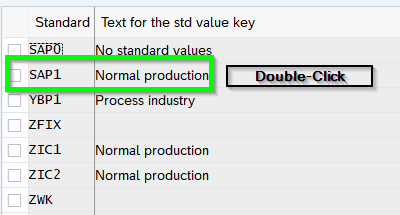

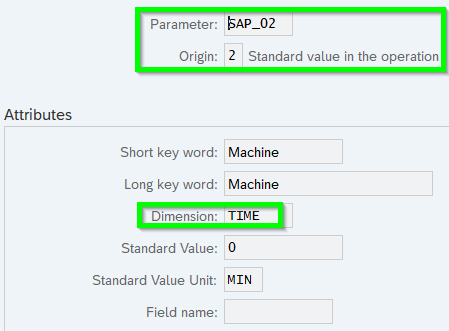

- Customizing of Standard Value Key (GER Vorgabewertschlüssel) via 0PCM:

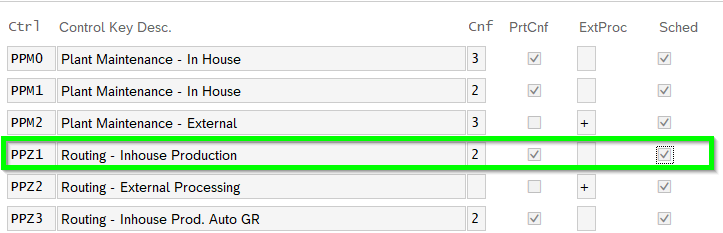

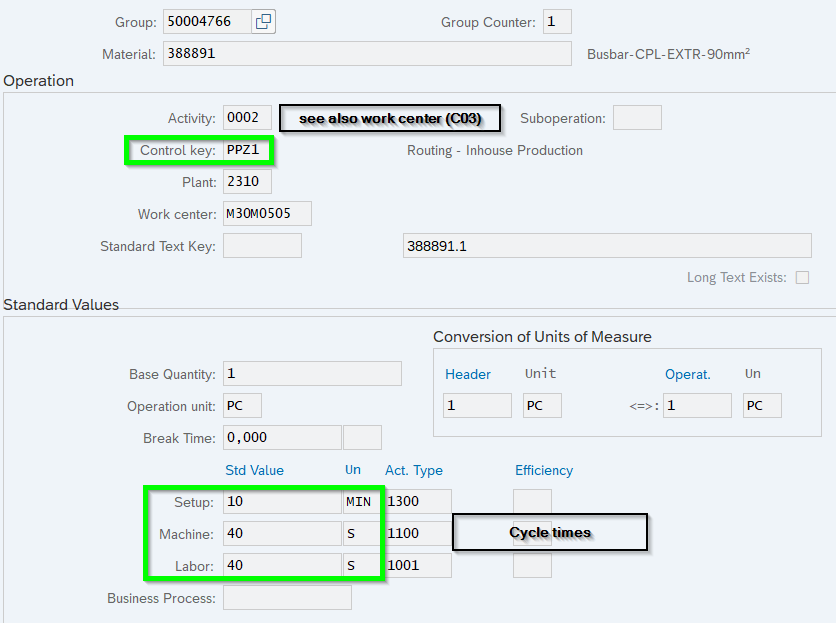

- Default Values: Most important the Control key (GER Steuerschlüssel) determines which business transactions should be executed. Cnf = Confirmation (GER Rückmeldung) 1 Milestone or 2 Confirmation required/ PrtCnfs tick means confirmations Slips (GER Rückmeldescheine) are printed/ ExtProc means internal or external process/ Sched tick means item being scheduled:

- The Control key is directly linked to an Operation (GER Vorgang) within the FAUF/ Routing. By setting different Control keys alternative machines, Milestone confirmation (i.e. confirmation on Operation 30 so automatically Operation 10 and 20 will be confirmed as well) can be set.

- Standard Text Key (GER Vorlagenschlüssel) you can maintain standard operations texts

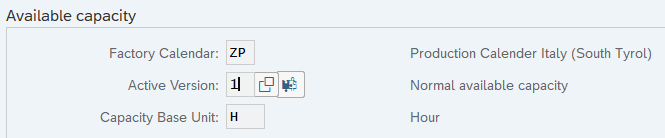

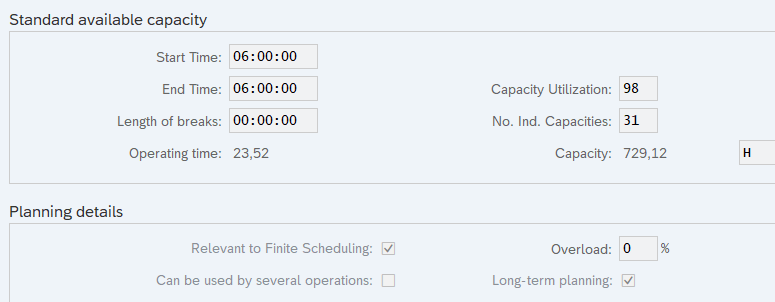

- Capacities: Mostly machine and/ or workers, jump to work center header to assign working calender, Standard available capacity or intervals and shifts:

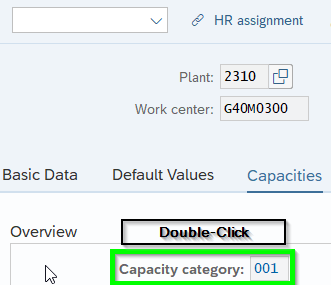

- You can use a Grouping to create shift sequences and shift definitions for special areas (for example, different plants or different areas of a plant) and select them when maintaining the available capacities of work centers

- Customizing Shift Program (OP4A):

- Maintenance of Breaks:

- Maintenance of Shifts incl. assignment of breaks:

- Last but not least maintain the Shift sequence (GER Schichtprogramme):

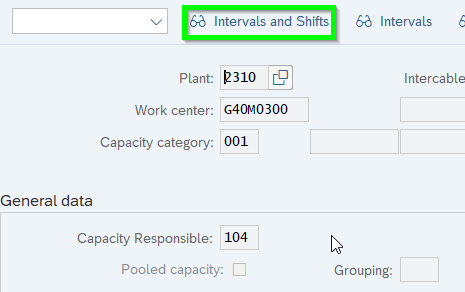

- Shift sequence (GER Schichtprogramme) will be assigned via following button:

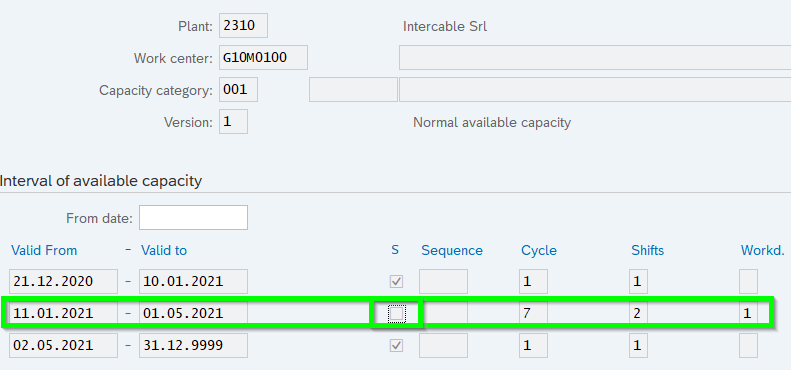

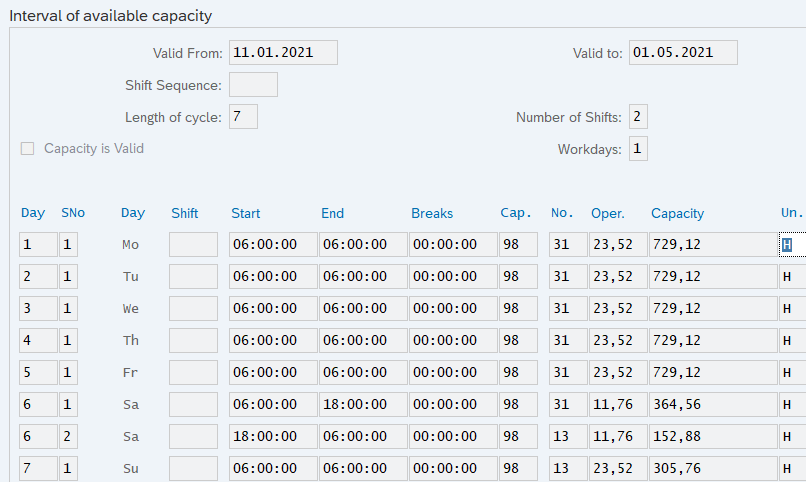

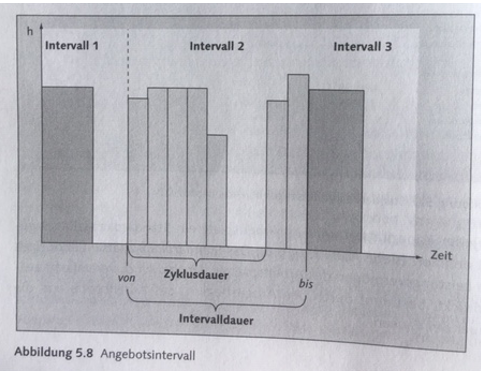

- If the Standard available capacity is not enough certain intervals can be maintained, i.e. timeframe 11.01.2021 – 01.05.2021:

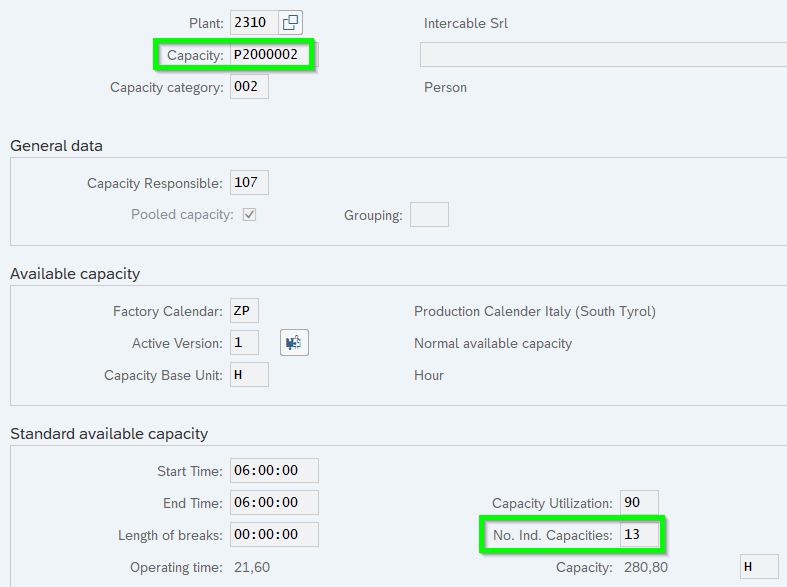

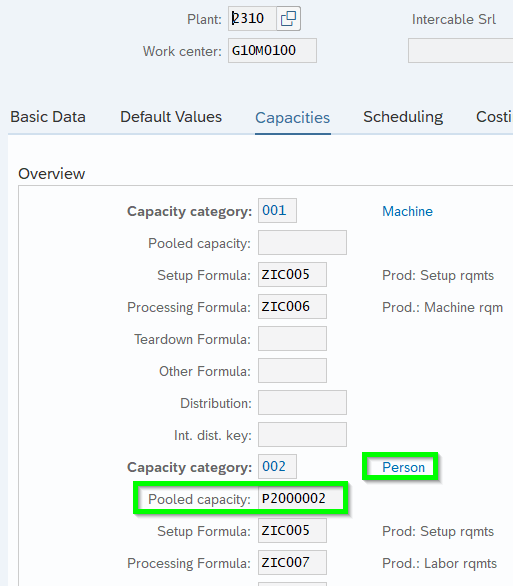

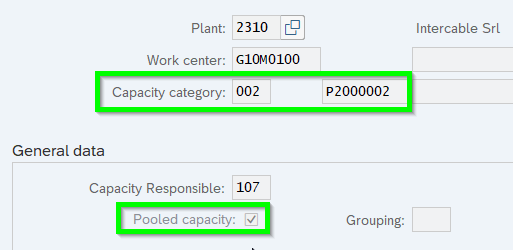

- Pool Capacity (CR11): For example workers who work on different machines can be assigned as pool capacity:

- Assignment to work center capacity:

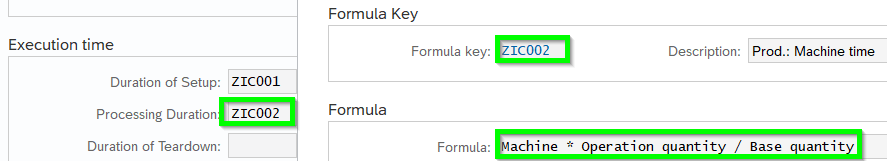

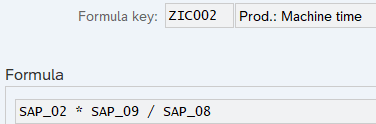

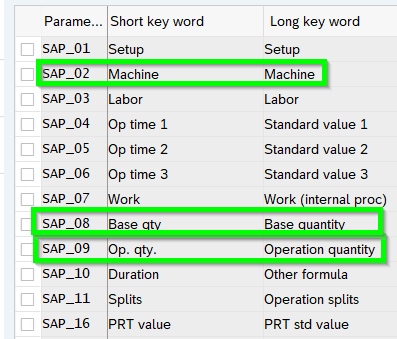

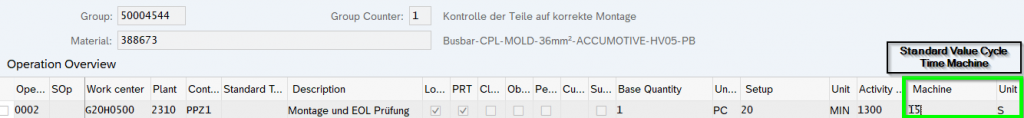

- Scheduling: When MRP performs scheduling of PLAUF/ FAUF the start and end Dates per Operation being calculated. The formula can be selected i.e. Machine (cycle time in sec. per Operation) multiplied by remaining qty. of PLAUF/FAUF divided by base qty.

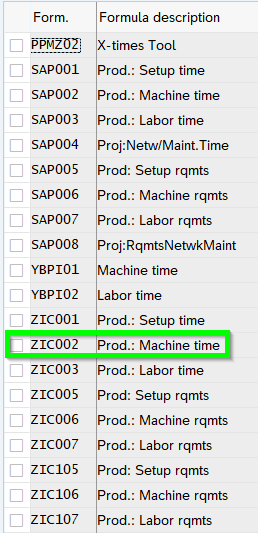

- In customizing OP21 all formulas for different purposes can be maintained:

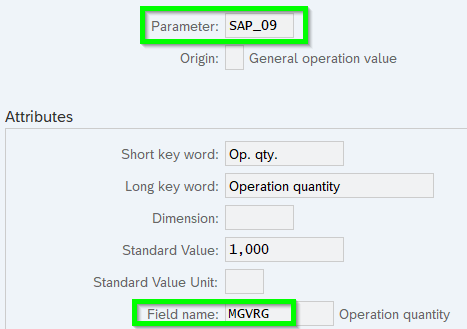

- In customizing OPCX variables/ parameters can be maintained:

- In customizing OPKM formula can be specified if Standard SAP formulas not being used:

- OPKL:

- SAP_09-MGVRG is in table KBED and equals the to produced qty. of material inside PLAUF/ FAUF

- SAP_02-2 Standard value in the Operation (GER Vorgang)

- The cycle time from Routing per Operation being used as SAP_02 machine:

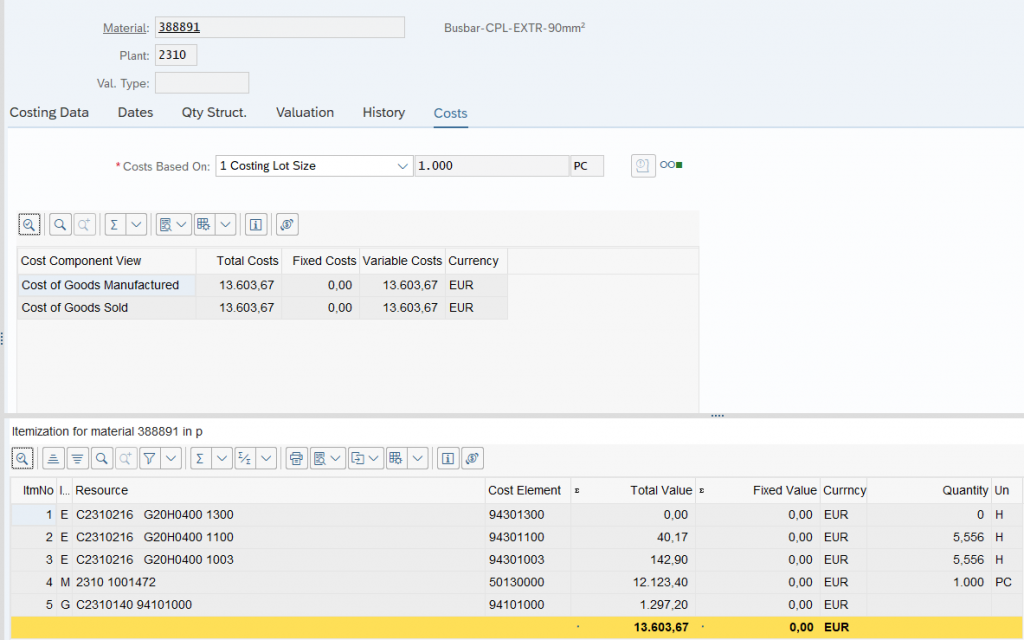

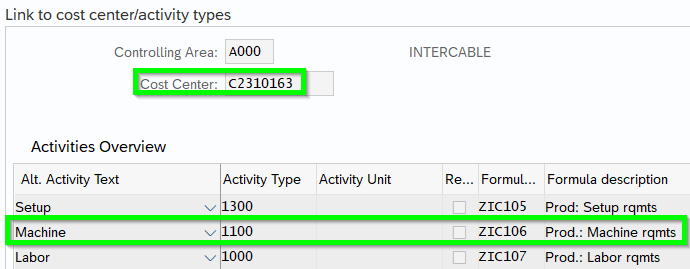

- Costing: Assign costing structure (Cost Center & Activity Type)

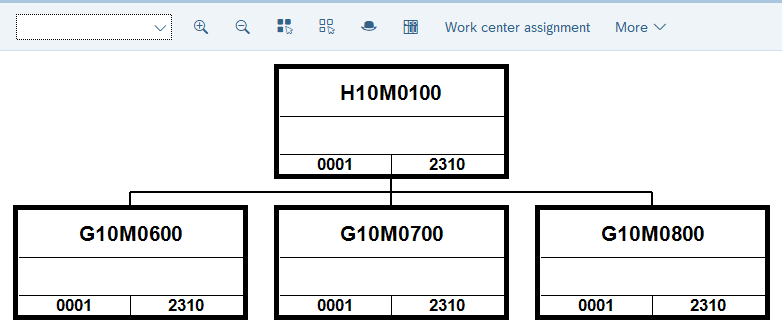

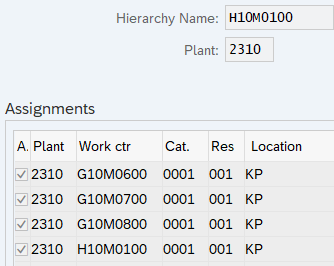

- Hierarchy relationships can be created to look for comprehensive capacity offer and capacity demand (CR23):

4. Routing (GER Arbeitsplan) (CA01)

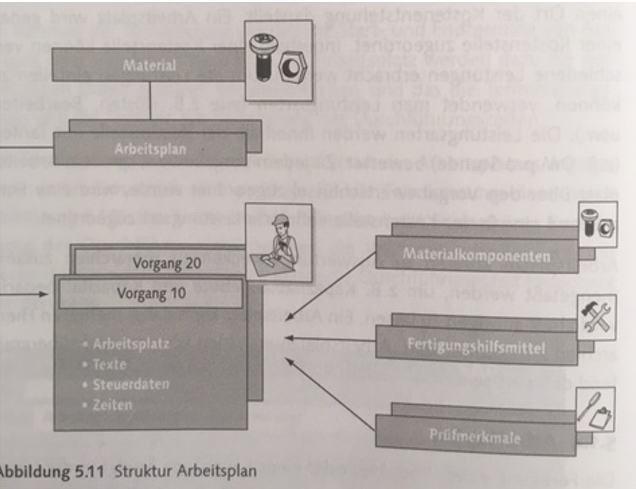

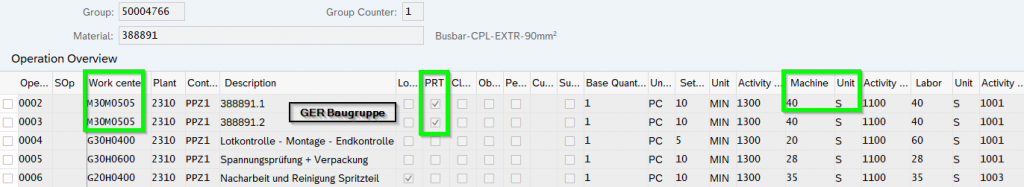

The information how and on which work center a certain material being produced is maintained in the routing (GER Arbeitsplan). It describes the sequence of the manufacturing as operations and will be used for PLAUF/ FAUF:

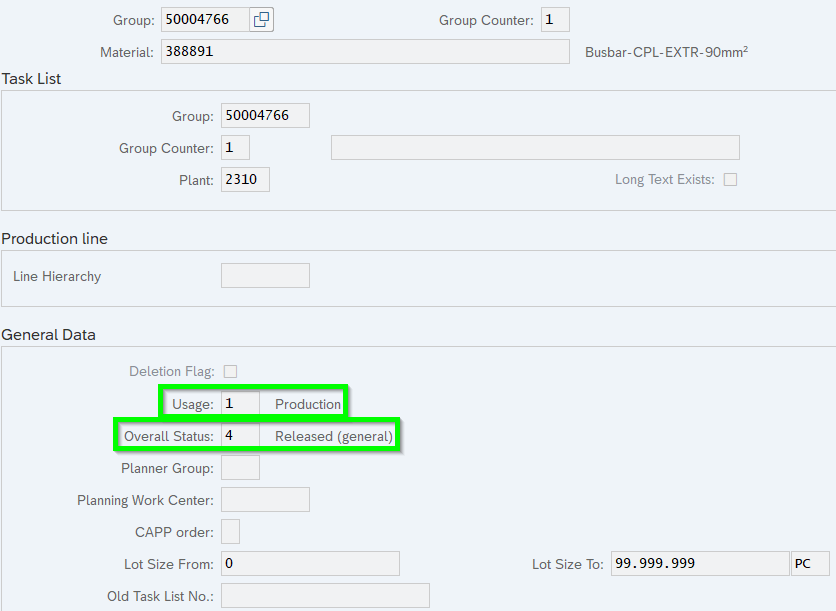

- Header: Usage i.e. 1 Production and Overall Status i.e. 4 released:

- Operations: A lot of functions can be maintained on operation level. The most important in the following.

- Normal Routing N (GER Normalarbeitsplan N) must assign a material number

- Reference Operation Set S (GER Standardplan S) will not be assigned to a material number

- Rate Routing R (GER Linienplan R) the data is the opposite – production volumes being maintained while the time is fixed. It describes how many will be produced in a certain timeframe.

- Customizing of Control Key (GER Steuerschlüssel): OPJ8

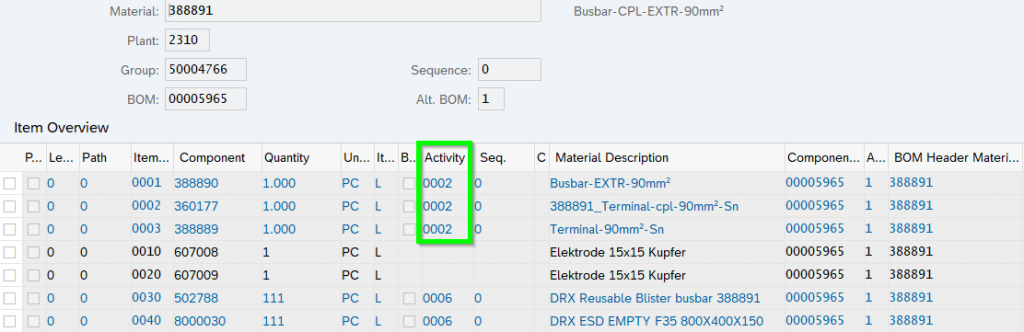

- Allocation (GER Komponenten) will also be assigned. You can specify for which Operation the component Needs to be supplied. If the duration between several Operation be substantial the date/ time for the supply can be more precise. Mostly the first operation being used:

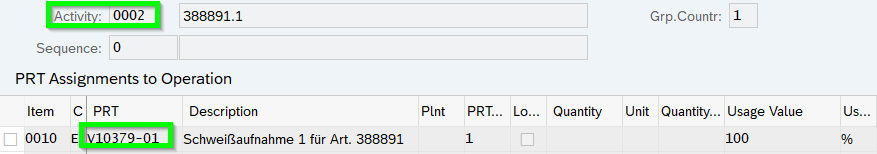

- PRT=Prod. resources/ Tools (GER FHM=Fertigungshilfsmittel) can be also maintained per activity/ operation. Details on PRT can be retrieved via IE03. Especially for moulding equipment counting can be maintained.

- CO33 Standard Trigger Point: Additional functions can be maintained if confirmations (GER Rückmeldungen) occur on certain operations i.e. release of next operations or workflow etc.

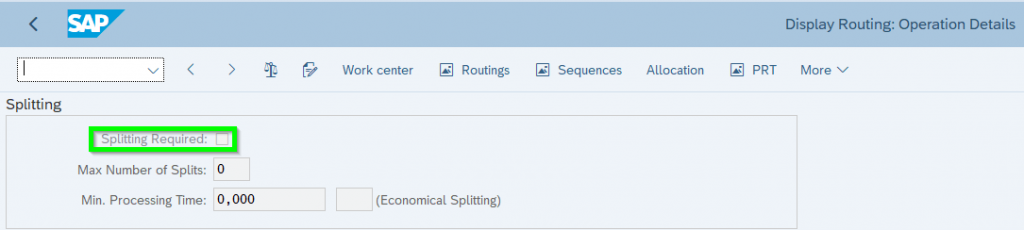

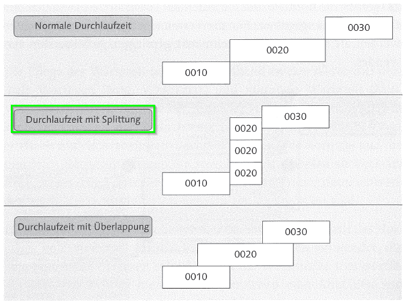

- Splitting: If an operation is being produced simultaneously on several machines or severall workers the operation can be split:

- This has an positive impact on the scheduling on machine time. On the other hand set up time needs increases when i.e. three machines run parallel. Here an overview for better understanding

5. Production Version (GER Fertigungsversion) Master Data-MRP 4 (MM01)

The Production Version links the Routing and the Bill-of-Material together. Hence a lot of combination as well timing or quota can be managed.

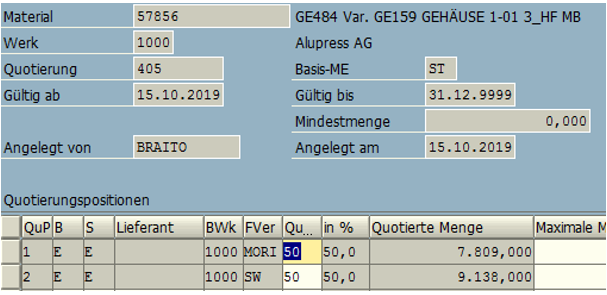

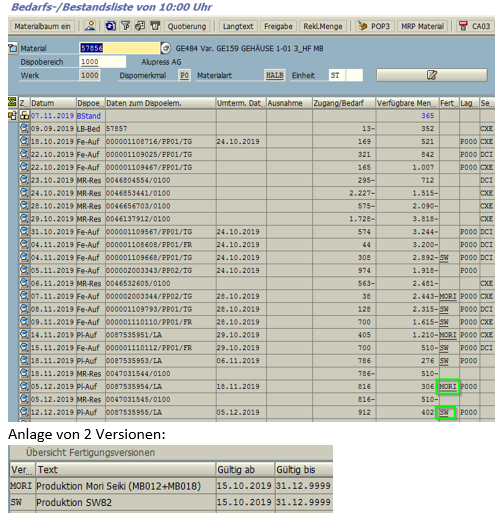

Here an example for Quota (Machining on Mori Seiki & SW82):

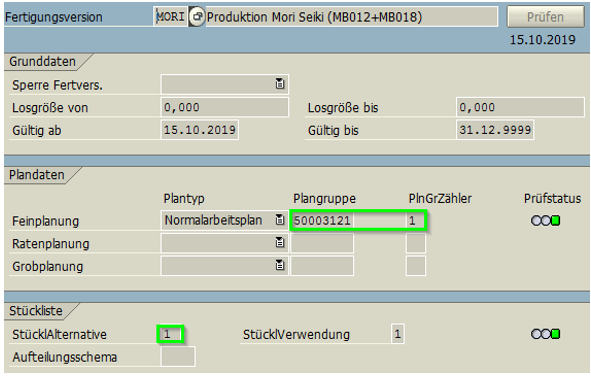

Production version „MORI“ refers to Routing 50003121 with Group Counter 1 and Alternative BOM1:

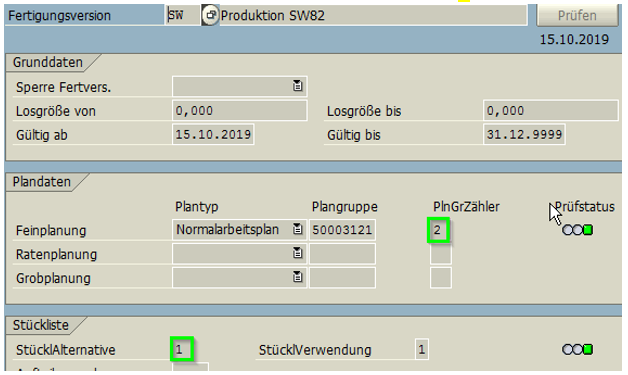

Production version „SW“ refers to Routing 50003121 with Group Counter 2 and Alternative BOM 2:

It is recommended to select 1:

With this setting both routings are parallel valid. Now the Quota MEQ1 needs to be maintained: