1. Sales and Operation Planning SOP (GER Absatz- und Produktionsgrobplanung)

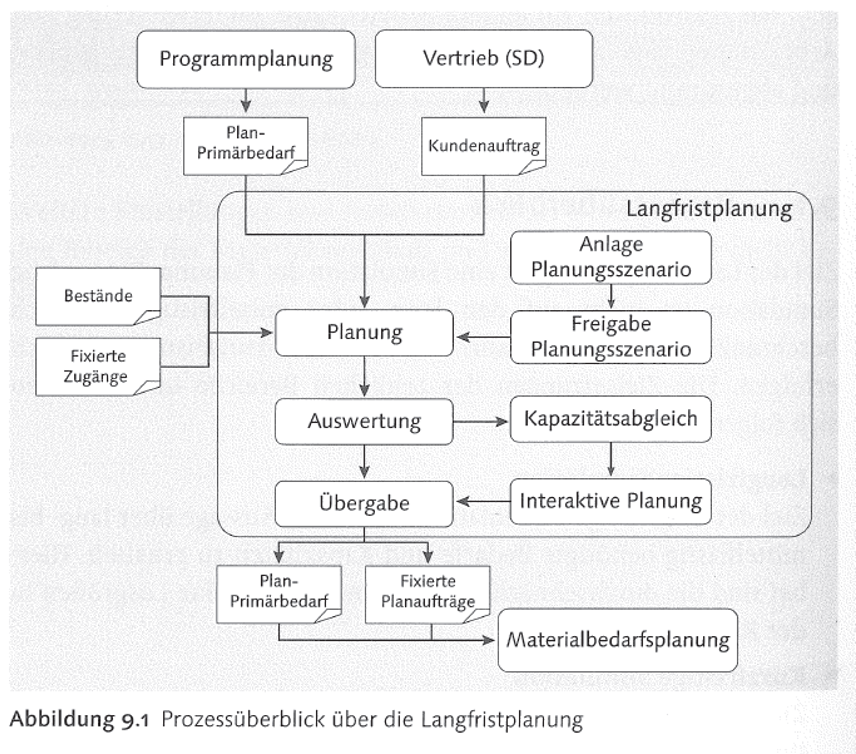

Standard Long-term Planning in SAP. Creation of Planning Sceanario via MS31. More Details in file „1910_BEW_SAP_PP_Modul_2“ from page 101-105:

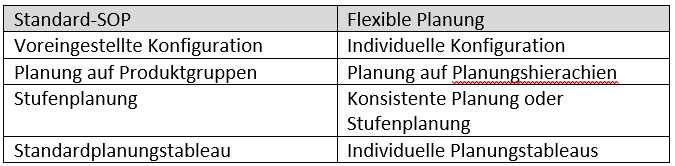

The Standard SOP Process in ERP looks as follows:

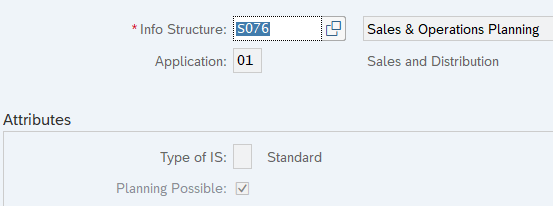

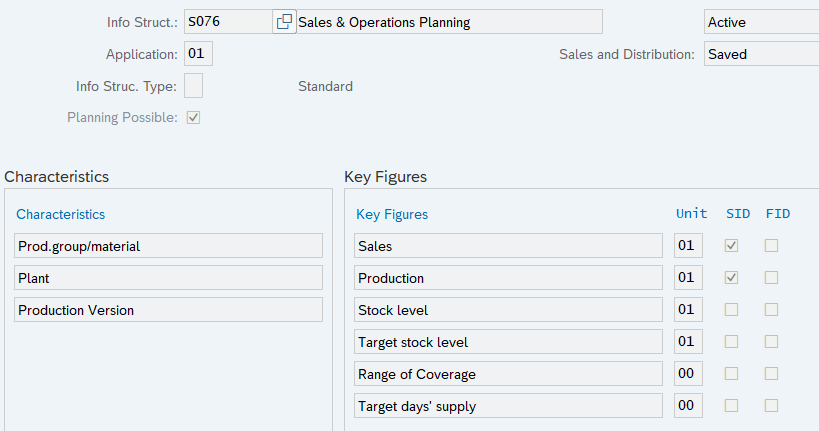

- Info Structure Standard S076 (MC23):

- Order of the Characteristics: 1. Product Group/ material 2. Plant 3. Production Version. Displayed as Key Figures like Sales and Production

- Further configuration via customizing MC7F (see details SAP book Produktionsplanung mit SAP ERP)

3. Programm Planning

In chapter 4 the data maintenance for Independent Requirement Planning VSF is described. In this chapter the parameters for the offset between VSF and related orders is goint to be explained.

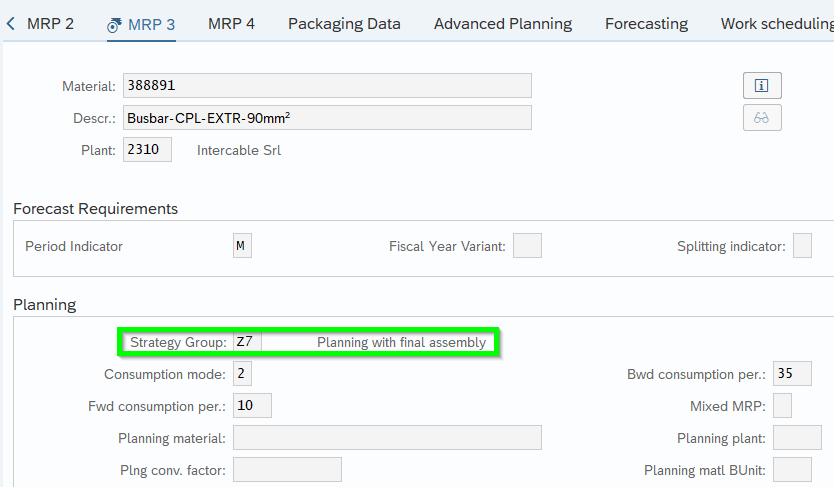

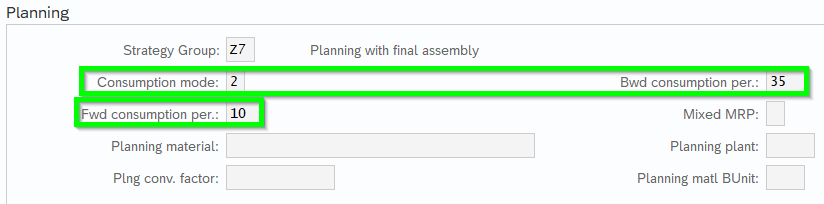

Very important is the Strategy Group (GER Strategiegruppe) in MM03-MRP4. Here the logic for offset being set. Z7 (=Standard 40) only offset VSF against customer orders or scheduling agreements but not against reservations:

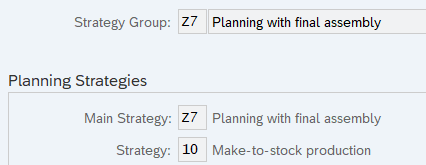

Customizing:

Customizing @DRX:

Consumption: The Logic is explaing in following files in german: Important parameters are marked green:

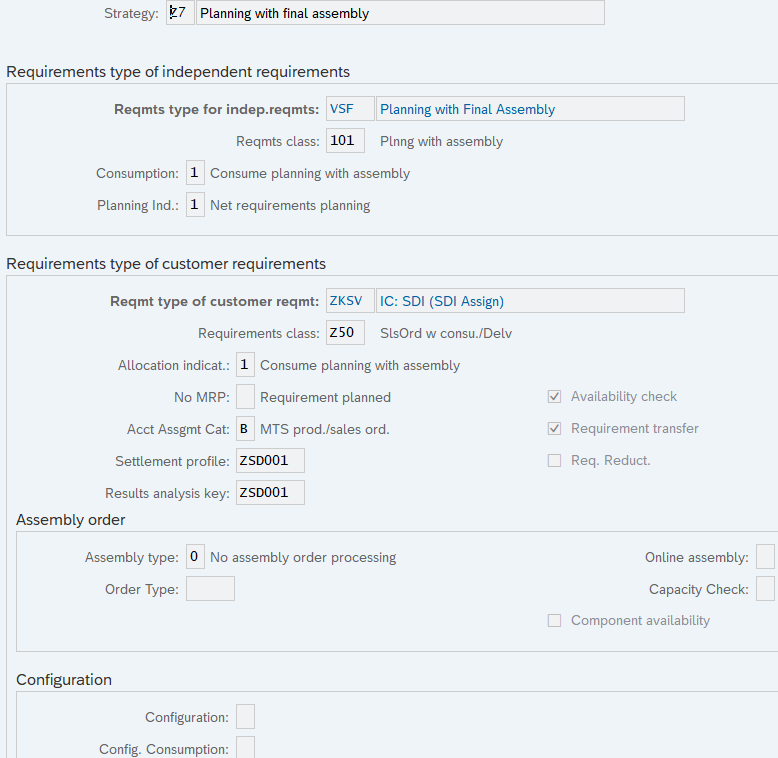

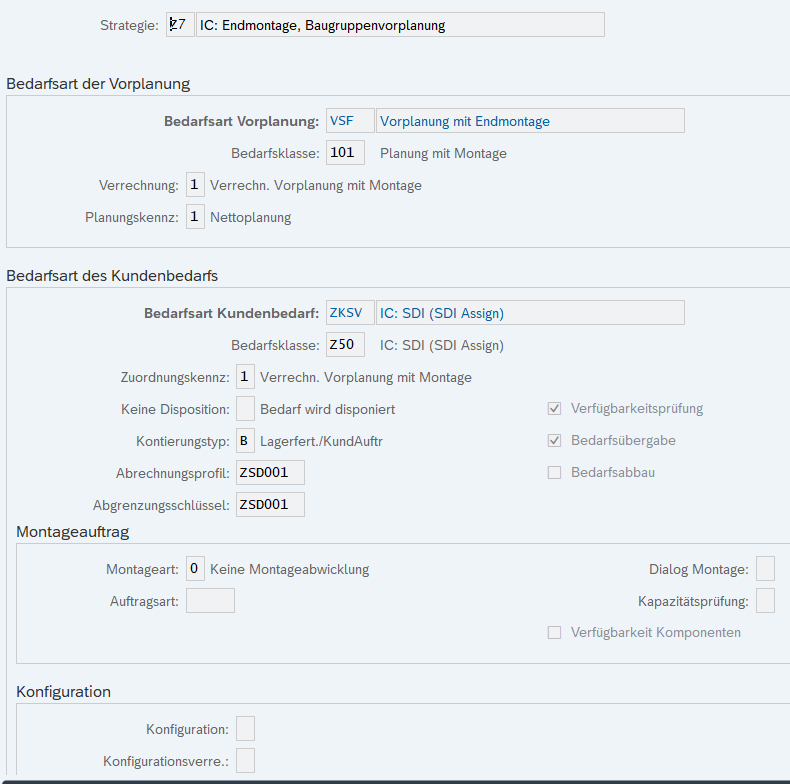

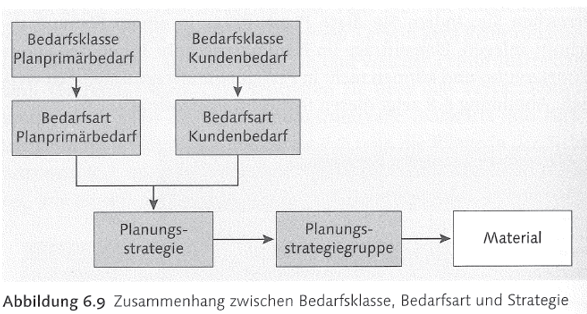

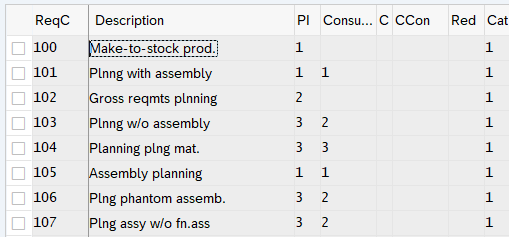

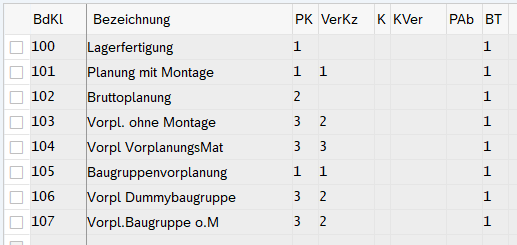

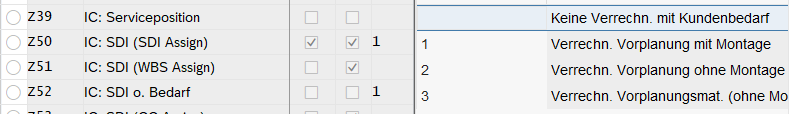

Requirement classes for VSF (GER Bedarfsklassen VSF): Is a central element where VSF being controlled if offsetting and where it should occur (Lagerabschnitt oder Planungsabschnitt):

Customizing OMPO:

Planungskennzeichen (PK): steuert, ob die Materialbedarfsplanung als Nettobedarfsrechnung (Wert 1), als Bruttoplanung (2) oder pro Kundeneinzelabschnitt (3) erfolgen soll

Verrechnungskennzeichen (Verk): steuert, inwiefern sich die Vorplanung mi den Kundenaufträgen verrechnen soll (- = keine Verrechnung; 1 = Verrechnung Vorplanung mit Endmontage; 2 = Verrechnung Vorplanung ohne Endmontage; 3 = Verrechnung Vorplanung mit Planungsmaterial)

Konfigurationskennzeichen (K): bestimmt, ob eine Konfiguration mittels Variantenkonfiguration erlaubt sein soll

Kennzeichen für Bedarfsabbau (PAb): steuert, wann der Planprimärbedarf abgebaut werden soll

Bedarfstyp (BT): definiert, ob die Bedarfsklasse für Planprimärbedarfe (Wert 1) oder für Kundenbedarfe (Wert 2) relevant sein soll

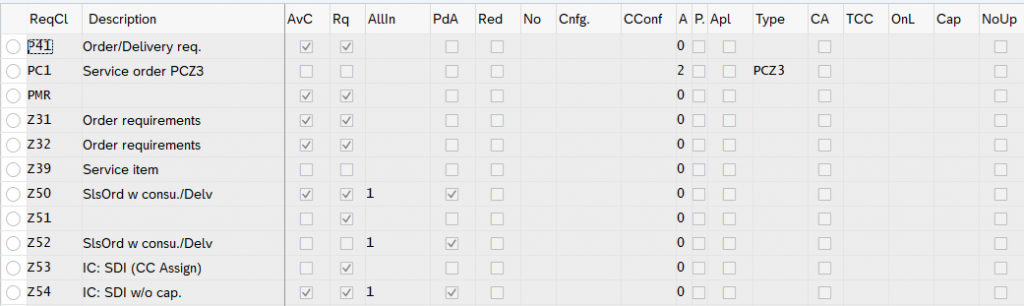

Customizing Customer demand OVZG:

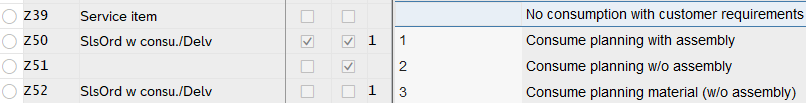

AllIn (GER ZuoKz = Zuordnungskennzeichen) offsetting:

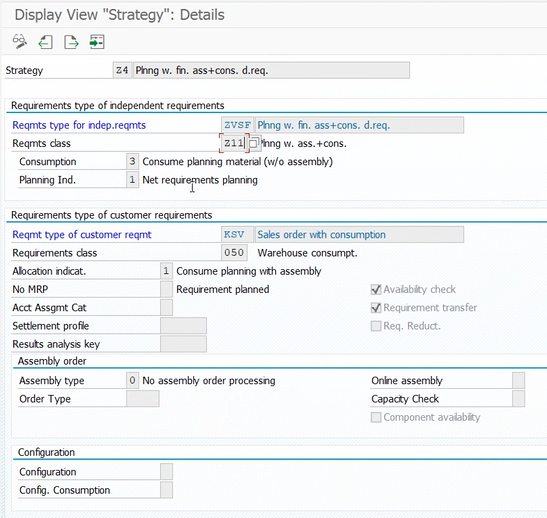

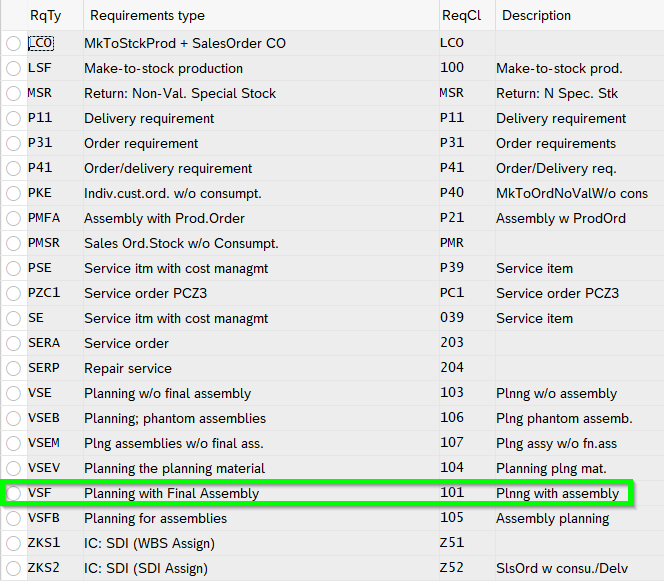

Customizing Requirment Types (GER Bedarfsarten) OMP1: Requirement Type (GER Bedarfsart) is connected to Requirement Class (GER Bedarfsklasse)

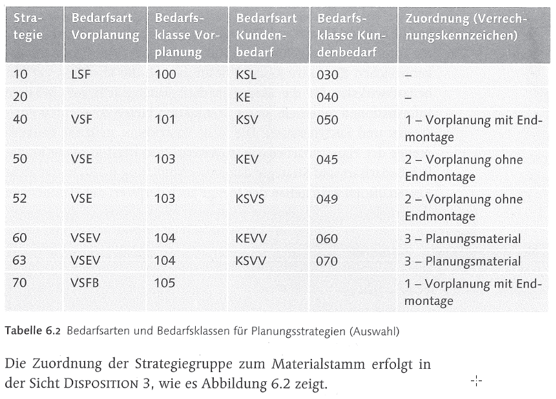

In the above screenshot of the configuation of Z7 the linakge between Requirement Types and Requirement Classes can be seen. Here is another overview of the SAP standard strategies:

4. Independent Requirement Planning – VSF (MD61)

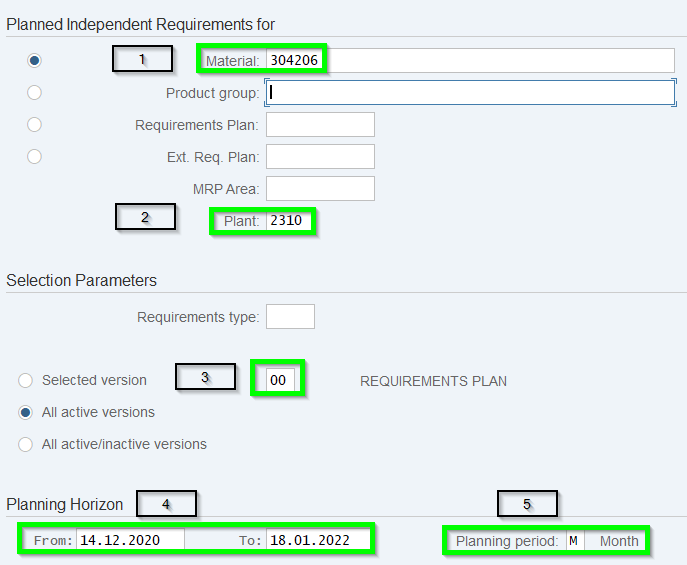

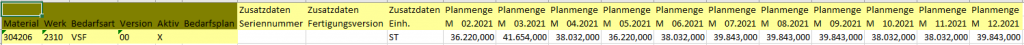

Mid- and long-term planned demand is essential for Sales, Inventory and Operating Planning (SIOP). In most cases customers will not provide demand forecast in such a long horizon. SAP is offering the method „Independent Requirements = VSF“ by utilizing different versions in alpha-numeric format of 2-digits (in example below 00). Since you can activate each version for MRP it is highly recommend to activate only one version to avoid creation of double VSF.

Versions for Sales (de-activated) and SCM (activated) being recommended. Sales versions can be used to retrieve planned demand mostly in period of month created on different timepoints. Sales versions can be created with Prefix-Plant (e.g. M=Munich) for nomination (MN), budget (MF) and/or rolling (MR) volumes. The history function gives the opportunity to track who has entered data and when. Please note that data structure is only based on part number level so the dimension customer is missing. For Sales purposes this is a big weakness when you have different customers for one part. In this case Sales has to aggregate the volumes of all customers. SAP Integrated Business Planning (IPB) or other Business Intelligence (BI) solutions need to be established. Based on the different Sales versions comparisons can be made from time to time.

The SCM version is MRP relevant and therefore more requirements being needed. Since the volumes are always being set on the first working day of the period it makes a big change if a March volume be set on 01.03.2021 or being split in 4 weeks and volumes being diverted to 01.03.2021 (week 9), 08.03.2021 (week 10) etc. In addition in most cases customizing will be set that VSF will be offset with dependent requirements like customer orders (CusOrd) or scheduling agreements (SchAgr). Especially when scheduling lines being available business side need to decide if VSF still need to be maintained in the horizon of the scheduling lines? If VSF are higher than dependent requirements it will create additional purchase requisitions (external supply) or planned orders (own production). This can cause to more stock on raw and/ or sub-components and unnecessary capacity reservations.

On the other hand if you keep the volumes activated you can run another report via MD73 to detect higher or lower dependent demand from customer. In line of disposition work certain reaction might be necessary. Further explanation please use below link:

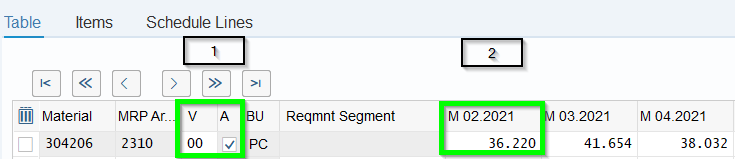

MD73Main Input being done via Transaction MD61:

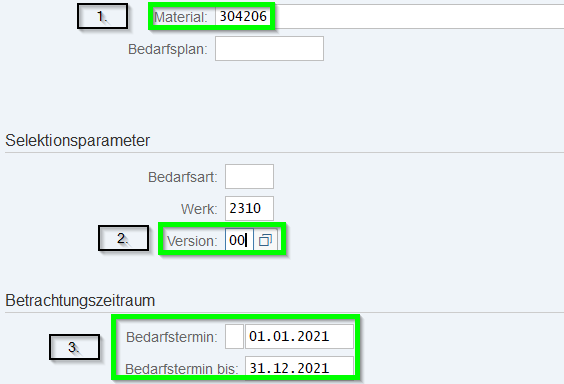

- Enter relevant material number

- Enter plant

- Enter version

- Select horizon

- Select month or week

After execution new window being opened:

- By ticking you activate the planned volume (No. 2) for MRP

- Based on the timeframe week or month you can enter volume for the relevant period

When you have created first planned demand you can look up via transaction MD63 or change with MD62. When you are in MD62 you easily can enter further parts for volume entry.

With Control+Y you can select data in the SAP transaction screen and either delete it with delete-key or copy via Control+C for to other part number. Business cases could be other versions for Sales, transfer same volumes for different part numbers (e.g. project family) or part number change. In 3rd case do not forget to delete whole line so no further VSF on old part number being created.

With the transaction MD79 you have the possibility to download an Excel for better investigations. For example compare Sales versions with SCM version or double-check that data being maintained correctly and no mistype volumes exist (e.g. instead 1.000 pcs. accidentally 10.000 pcs. being entered).

- Either specific part number

- Or complete version 00 SCM

- Set relevant horizon

In the chapter querys further user friendly alternatives can be found.

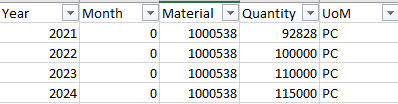

In the following a customer developed upload transaction being explained which optimize the mass data maintenance of VSF.

- Select drive path for upload file

- Select plant

- Select version

- Language key, this is used for the unit of measurement

- Ticking makes upload VSF MRP relevant, so for

Sales version untick - With this selection, a yearly volume will be split by month according to working calender

- With this selection, a monthly volume will be split by week according to working calender

- This goes with No. 7 – the number entered makes the monthly split into weeks with the following rule: The

system takes the date when using upload transaction, then choose next month and from this month the entered number will be split into weeks, e.g. upload date 14.12.2021 –> first month January 2021 –> enter 13 –> weeks until January 2022 - Do not tick so testing mode being started to check if mistakes included in Excel file; if check is ok then activate so upload being done int MD61

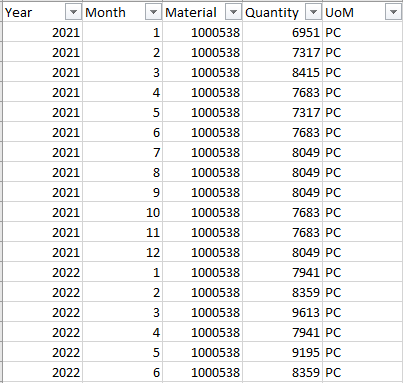

Here the Excel format for No. 6 Budget

Here the Excel Format for No. 7 Intercompany